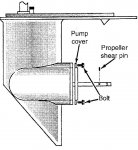

I tend to do more harm than good when I work on a motor. I just bought a 1995 3.3hp Johnson. The motor was hardly used, but it’s the newest motor I’ve ever had so I wanted to do the typical maintenance on a motor that hasn’t been used in a while. This included replacing the impeller, which is located behind the prop in the driveshaft. After replacing the impeller, I was screwing the pump cover back on and ended up stripping the threads in the driveshaft. One step forward, two steps back. Any suggestions on how to fix this? I was thinking either longer or thicker bolts, but if that’s the case, do I need a machine shop to re-drill the holes? Below is an illustration from the manual and a few pictures I took.

Last edited: