Re: Transom Hight

This should help you understand how the Transom Height and Motor work together...

Shaft length Outboard motor shaft lengths are standardized to fit 15-inch, 20-inch and 25-inch

transoms. If the shaft is too long it will extend farther into the water than necessary creating

drag, which will impair performance and fuel economy. If the shaft is too short, the motor will be prone to ventilation. Even worse, if the water intake ports on the lower unit are not sufficiently submerged, engine overheating is likely, which can result in severe damages.

[h=2]Operational issues[/h][h=3]Motor mounting height[/h]Motor height on the

transom is an important factor in achieving optimal performance. The motor should be as high as possible without ventilating or loss of water pressure. This minimizes the effect of

hydrodynamic drag while underway, allowing for greater speed. Generally, the antiventilation plate should be about the same height as, or up to two inches higher than, the

keel, with the motor in neutral trim.

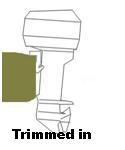

[h=3]Trim[/h]Trim is the angle of the motor in relation to the hull, as illustrated below. The ideal trim angle is the one in which the boat rides level, with most of the hull on the surface instead of plowing through the water.

If the motor is trimmed out too far, the

bow will ride too high in the water. With too little trim, the bow rides too low. The optimal trim setting will vary depending on many factors including speed, hull design, weight and balance, and conditions on the water (wind and waves). Many large outboards are equipped with

power trim, an electric motor on the mounting bracket, with a switch at the helm that enables the operator to adjust the trim angle on the fly. In this case, the motor should be trimmed fully in to start, and trimmed out (with an eye on the

tachometer) as the boat gains momentum, until it reaches the point just before ventilation begins or further trim adjustment results in an

RPM increase with no increase in speed. Motors not equipped with power trim are manually adjustable using a pin called a topper tilt lock.

[h=3]Ventilation[/h]Ventilation is a phenomenon that occurs when surface air or exhaust gas (in the case of motors equipped with through-hub exhaust) is drawn into the spinning propeller blades. With the propeller pushing mostly air instead of water, the load on the engine is greatly reduced, causing the engine to race and the prop to spin fast enough to result in

cavitation, at which point little thrust is generated at all. The condition continues until the prop slows enough for the air bubbles to rise to the surface.[SUP]

[4][/SUP] The primary causes of ventilation are: motor mounted too high, motor trimmed out excessively, damage to the antiventilation plate, damage to propeller, foreign object lodged in the diffuser ring.

[h=3]Cavitation[/h]

Cavitation as it relates to outboard motors is often the result of a foreign object such as marine vegetation caught on the lower unit interrupting the flow of water into the propeller blades.