I was inspired by PeterMarcus to go ahead and dig into my transom. I have a Bayliner 1950 with a 125 hp I/O in it. I had noticed that I was getting a serious amount of wood rot on the lower part of opening and decided the day had come to take care of the issue.

A friend came over and helped get everything apart. With the help of a small winch from Harbor Freight and the use of a come-along hooked to my garage rafters, I was able to get the outdrive, collar, and engine apart pretty easily. I had taken the outdrive off several years ago to redo a bunch of gaskets, tubing, and bushings.

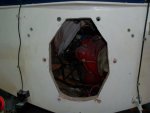

After getting access to the hole in the transom I could see the extent of the wood rot of the transom doubler. I was more than I expected and hoped. By the time I finished getting all the rotted wood out, there was only about 20% of the rest of the doubler that was any good. So I decided to just take it all out and redo it all cleanly. I've got some pictures that I hope show what's been done so far - if I can figure out how to attach pictures. I've only attached a few of the many I've taken just to give an idea of the work going on.

I'll add to this as I get further along.

A friend came over and helped get everything apart. With the help of a small winch from Harbor Freight and the use of a come-along hooked to my garage rafters, I was able to get the outdrive, collar, and engine apart pretty easily. I had taken the outdrive off several years ago to redo a bunch of gaskets, tubing, and bushings.

After getting access to the hole in the transom I could see the extent of the wood rot of the transom doubler. I was more than I expected and hoped. By the time I finished getting all the rotted wood out, there was only about 20% of the rest of the doubler that was any good. So I decided to just take it all out and redo it all cleanly. I've got some pictures that I hope show what's been done so far - if I can figure out how to attach pictures. I've only attached a few of the many I've taken just to give an idea of the work going on.

I'll add to this as I get further along.