Re: Defeated!!!!!!

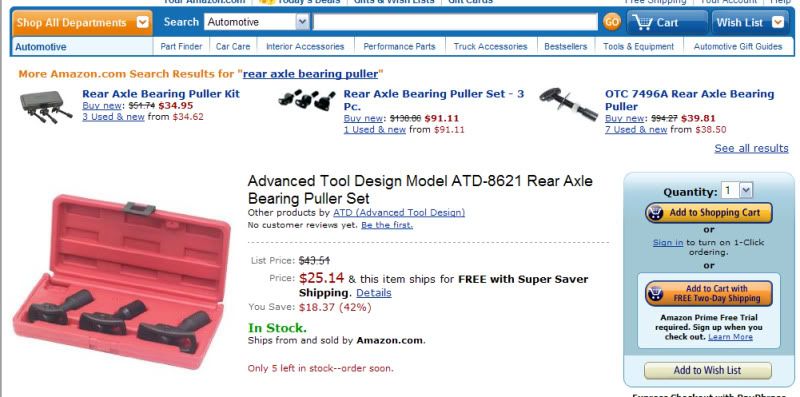

the part was 1/4 thick and about an inch wide and about 1/8 overhanging each side of the inner race when fitted.obviously a hole for the threaded rod to pass through .this could be passed through the centre of the bearing with your fingers and twisted into position.now you say how you get the nut on the back.well!!the nut was layed in the area on the aft side of the rubber diaphragm in which my tool was passed through too. the threaded bar went through the bearing ,through the tool and then i screwed the nut on which was being held slightly with the rubber diaphragm.you could have welded the nut on or put a thread through the bar.its fiddly but it worked for me.will try and get pictures uploaded to the site at a later date as im in the falklands until next week.the above tool would work too but i manufactured mine in about half an hour with a hacksaw a file and a drill.regards steve

the part was 1/4 thick and about an inch wide and about 1/8 overhanging each side of the inner race when fitted.obviously a hole for the threaded rod to pass through .this could be passed through the centre of the bearing with your fingers and twisted into position.now you say how you get the nut on the back.well!!the nut was layed in the area on the aft side of the rubber diaphragm in which my tool was passed through too. the threaded bar went through the bearing ,through the tool and then i screwed the nut on which was being held slightly with the rubber diaphragm.you could have welded the nut on or put a thread through the bar.its fiddly but it worked for me.will try and get pictures uploaded to the site at a later date as im in the falklands until next week.the above tool would work too but i manufactured mine in about half an hour with a hacksaw a file and a drill.regards steve