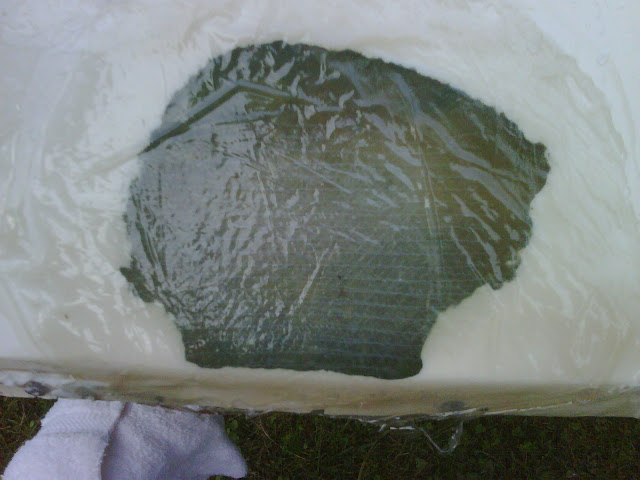

Re: Advice please! Fiberglass boat hull hole patch (pics)

Oops hey buddy, i figured you might have gotten busy or else been diverted on energies of higher priority. I know it doesn't look like i know what i am doing, wow, after that entire shotgun hole episode.

Now after i look back, i continually think to myself, what an idiot? I should've known better than to do this, i was calling myself getting beyond such deep cracks in an area about the size of a football.

But, now i know i could've fixed this area without cutting it out. IDIOT!!!

Anyway, i have to repair it now for sure, and i have a good working knowledge of fiberglass just maybe not all of the pertinetn details needed for this job. I want to ensure that i get a great bond and that the layers are layered correctly without any air pockets.

Is there anyway Oops, that you might could provide the list of weighted material you would advise on the inside of this hole to include the amount of layers?

Then how many would you provide on the exterior? I was thinking in the ballpark of 6-8 layers underneath with each layer overlapping 1/2" larger than the layer prior?

Then the set time between several layers?

How far must i extend out in the inside for this hole that meaures up to 14" long for a good bond for the duration of the life of the boat?

Thanks for all of your help and your time Oops that you have been providing up to this time, for that i am greatly appreciative?

Do you duck hunt Oops? If you do i might could make you a duck call as a token of appreciation for all of your help?

quackycalls.com

Thanks, Chris