Running without an airhorn might lean out the mix. Additionally, I think there was reference in a prior thread to the air horn or the engine cover affecting tuned exhaust (i.e., operating without the airhorn might affect factory exhaust tuning). Running without it might give you a hotter look -- but the motor might also run hotter (as in hotter temp) or a little ragged.

If you want to hotrod a little, you might try misting water at the open carbs with the engine warmed up and running at a high idle. Would not want to hydrolock it -- just an attempt to clear some additional carbon, similar to what boobie mentioned although I don't know if he would approve of the "steam cleaning" method. It's an old-time fix with carbureted cars -- more controversial with two-cycle outboards. If more comfortable, could do that with seafoam or something similar.

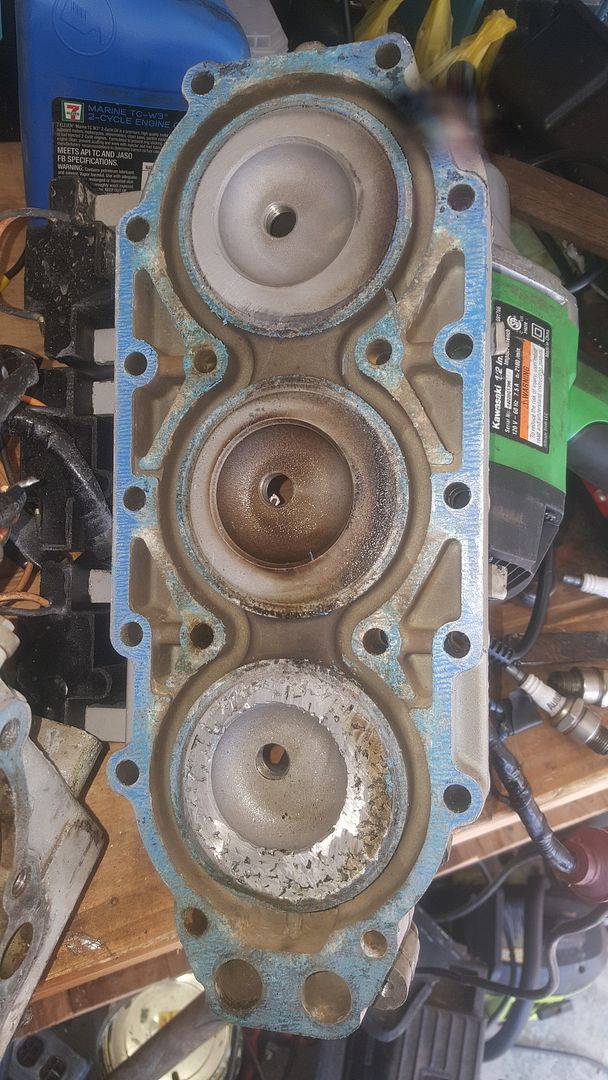

Don't know if the head and covers are back on. If not, suggest replacing gaskets and resurfacing covers, then torquing to specs and retorque after running. Torque pattern is important (usually a clockwise circular pattern, beginning in the middle). It's possible there are other issues, of course, but you might find the compression evens out -- can look further if the simpler fix doesn't work.