cfauvel

Chief Petty Officer

- Joined

- Aug 16, 2005

- Messages

- 645

I may have several issues at the same time.

Normally the motor at WOT runs at 5800 rpm and jumps on plane in <4 seconds. (as recently as two weeks ago).

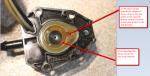

what I have done since then is a whole thread on the VRO's oil mechanism and test on the assembly. So that assembly has been taken apart to see the diaphragms and put back together and run at idle in the yard.

also the voltage regulator was changed due to lack of tach pulse and over charge to batteries.

So those are the things I've done prior to today.

Symptom:

mashing the throttle the boat wouldn't get up on plane and die, so checked the connections to the fuel pump, played with primer bulb and got it hard and tried again numerous times

It finally went, but it got only to 4000 rpm

(temp rose above normal (gauge), but didn't blow horn)

then it died again and did same song and dance as before....

...out of the blue it would act near normal and get up on plane and run to 5000rpm +....BUT if you slowed down for a no-wake zone it would die and take a lot of effort to get it running again....then out of the blue it would work again.

(when it acted near normal it wouldn't jump on plane as expected)

once we got done with the no-wake zones and it acted normally we took it for a 20+ mile cruise from 3000 - 4400 rpm with no problems at all... cruised at 25mph, 35 mp and 40 mph without a hitch...so seemed like a low speed issue.

When I got home just now I took out the three starboard plugs,....the two bottom ones were a nice brown, the top one was a little wet, when I noticed melted coil potting onto a water tube.

I Imagine a coil going out would show itself as a lack of expected power.

What would cause the coil to heat up so bad to melt the potting?

Going outside right now to check the port side and do my stator OHM and voltage tests...I'll probably make a video and take photos of that,.....

At first my gut said fuel pump as that was one of the last things I played with....but being able to run at 4000+ rpm for a few hours kind of leads me away from that....right?

Normally the motor at WOT runs at 5800 rpm and jumps on plane in <4 seconds. (as recently as two weeks ago).

what I have done since then is a whole thread on the VRO's oil mechanism and test on the assembly. So that assembly has been taken apart to see the diaphragms and put back together and run at idle in the yard.

also the voltage regulator was changed due to lack of tach pulse and over charge to batteries.

So those are the things I've done prior to today.

Symptom:

mashing the throttle the boat wouldn't get up on plane and die, so checked the connections to the fuel pump, played with primer bulb and got it hard and tried again numerous times

It finally went, but it got only to 4000 rpm

(temp rose above normal (gauge), but didn't blow horn)

then it died again and did same song and dance as before....

...out of the blue it would act near normal and get up on plane and run to 5000rpm +....BUT if you slowed down for a no-wake zone it would die and take a lot of effort to get it running again....then out of the blue it would work again.

(when it acted near normal it wouldn't jump on plane as expected)

once we got done with the no-wake zones and it acted normally we took it for a 20+ mile cruise from 3000 - 4400 rpm with no problems at all... cruised at 25mph, 35 mp and 40 mph without a hitch...so seemed like a low speed issue.

When I got home just now I took out the three starboard plugs,....the two bottom ones were a nice brown, the top one was a little wet, when I noticed melted coil potting onto a water tube.

I Imagine a coil going out would show itself as a lack of expected power.

What would cause the coil to heat up so bad to melt the potting?

Going outside right now to check the port side and do my stator OHM and voltage tests...I'll probably make a video and take photos of that,.....

At first my gut said fuel pump as that was one of the last things I played with....but being able to run at 4000+ rpm for a few hours kind of leads me away from that....right?

Last edited: