nola mike

Vice Admiral

- Joined

- Apr 22, 2009

- Messages

- 5,786

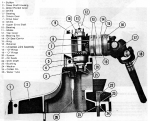

Ugh, I don't know that I'm ever getting this thing back on the water. Had planned on replacing the lower driveshaft seal tomorrow. The drive had been off and laying on its side. When I picked it up I noticed a small puddle; looks like it's coming from the upper, and leaking into the exhaust cavity. Weird thing is that when I put it on a stand, I pulled the lower plug. Initial oz or 2 looked good (but it had been laying on its side, so any water wouldn't necessarily come out first). Then I remembered that I should probably check the level before I drained it, so put the lower screw in, pulled the vent screw--and lube started pouring out the vent. Quite a bit. I don't get that.

So, what's the likely source of the leak? I'm going to pressure test in the AM anyway, but would like to know where I should look. The yoke and u-joints/bellows were dry, and the input shaft seal was replaced last season (maybe 2?).

Going to annoy me to have to wait on parts to get this on the water (or worse). I have a spare drive that I replaced the input shaft seal on last year, but it whined when I put it back together, so put this one back on. Guessing I'd have to remove the input shaft on that one and recheck the preload at least.

So, what's the likely source of the leak? I'm going to pressure test in the AM anyway, but would like to know where I should look. The yoke and u-joints/bellows were dry, and the input shaft seal was replaced last season (maybe 2?).

Going to annoy me to have to wait on parts to get this on the water (or worse). I have a spare drive that I replaced the input shaft seal on last year, but it whined when I put it back together, so put this one back on. Guessing I'd have to remove the input shaft on that one and recheck the preload at least.