RogersJetboat454

Commander

- Joined

- Jul 9, 2010

- Messages

- 2,964

Hello all!

It’s been many years since I’ve posted on Iboats. Good to see some of the old hands are still around after thumbing through a few of the newer posts.

I come here asking for some feedback on an issue I’m having with old friend. A ‘56 Fleetwin I freshened up back in 2012 that I did a four page post on in this thread;

forums.iboats.com

forums.iboats.com

At the time the motor was owned by my cousin, and has been since given to me.

I’d be surprised if it had more than 3 gallons of fuel run through it since I went through it. Probably the main reason being is it still had lackluster top end performance. Starting/midrange it runs great.

A quick punch list of the stuff done during its cleanup back when:

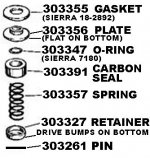

-LU completely resealed, with lower drive shaft replaced (spring had expanded).

-New water pump

-All powerhead gaskets had been replaced w/ new ones from Vintage Outboard.

-Carb cleaned/rebuilt, NOS low speed needle installed.

-Fresh OE set of points/condensers installed.

-7MM Copper core wires installed

-Set points based on flywheel marks

Already had coils replaced previously, and seemed in good shape.

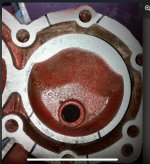

During the refresh a couple issues were found. The major one was the head gasket for the lower cylinder had blown, and was allowing water ingress. I leveled both the head surface, and deck surface on a piece of glass with 600 grit paper, and the new head gasket had been installed.

Second issue found was some pitting in the upper cylinder, but I was told that the 20:1 oil ratio I run in this would make this a non-issue. If I recall correctly, this was making around 90psi on both cylinders when I was done putting it back together.

So, that brings me back to now. Still has lackluster top end pushing either a 12ft, or 14ft aluminum boat. The neighbors little 5.5hp Ted Williams on the 12ft boat will give it a run for it’s money.

First thought was perhaps I’m loosing spark, but a spark gap tester installed on either cylinder is looking constant, and hot blue.

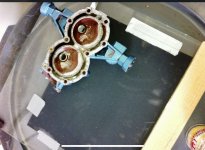

Took apart the reed valves (which I hadn’t touched in 2012). Was a bit of crust on the aluminum plate, but nothing crazy. Cleaned the valves/plate with scotch brite, and 600 grit. Carb checked to be sure I was getting WOT. Didn’t seem to make much of a difference.

Final check I did, since the lower plug looked a little bit cleaner than the upper, ran it with the lower plug out, and was getting a bit of a mist of water out of the lower cylinder spraying on my hand.

Ah-haaa?

Given that the block/head should be square, with a new gasket installed, and the head bolts torqued to factory specs, I wouldn’t expect it to have a blown head gasket. Also the exhaust plate was taken off, cleaned, inspected during the refresh. No signs of pitting/holes at the time. New gasket was installed with a light coat of 3M 847.

Im at a loss for where the water may be coming from, short of a crack in either the block/head that wasn’t apparent. My

Only other thought is it possibly normal for that cylinder to pull water up through the exhaust ports when there’s no pressure from the combustion process pushing it out?

Sorry for the novel length post, but I thought it’s best to get all the facts right out on the table.

Thanks!

It’s been many years since I’ve posted on Iboats. Good to see some of the old hands are still around after thumbing through a few of the newer posts.

I come here asking for some feedback on an issue I’m having with old friend. A ‘56 Fleetwin I freshened up back in 2012 that I did a four page post on in this thread;

1956 Evinrude Fleetwin freshen-up

Suppose I will add another thread about the humble little Fleetwin. This is my cousin's motor, and in fact the first motor I got to operate solo some 15+ years ago. I have fond memories of taking her out to explore the lake (in our general area of course), as well as my cousins I'm sure...

forums.iboats.com

forums.iboats.com

At the time the motor was owned by my cousin, and has been since given to me.

I’d be surprised if it had more than 3 gallons of fuel run through it since I went through it. Probably the main reason being is it still had lackluster top end performance. Starting/midrange it runs great.

A quick punch list of the stuff done during its cleanup back when:

-LU completely resealed, with lower drive shaft replaced (spring had expanded).

-New water pump

-All powerhead gaskets had been replaced w/ new ones from Vintage Outboard.

-Carb cleaned/rebuilt, NOS low speed needle installed.

-Fresh OE set of points/condensers installed.

-7MM Copper core wires installed

-Set points based on flywheel marks

Already had coils replaced previously, and seemed in good shape.

During the refresh a couple issues were found. The major one was the head gasket for the lower cylinder had blown, and was allowing water ingress. I leveled both the head surface, and deck surface on a piece of glass with 600 grit paper, and the new head gasket had been installed.

Second issue found was some pitting in the upper cylinder, but I was told that the 20:1 oil ratio I run in this would make this a non-issue. If I recall correctly, this was making around 90psi on both cylinders when I was done putting it back together.

So, that brings me back to now. Still has lackluster top end pushing either a 12ft, or 14ft aluminum boat. The neighbors little 5.5hp Ted Williams on the 12ft boat will give it a run for it’s money.

First thought was perhaps I’m loosing spark, but a spark gap tester installed on either cylinder is looking constant, and hot blue.

Took apart the reed valves (which I hadn’t touched in 2012). Was a bit of crust on the aluminum plate, but nothing crazy. Cleaned the valves/plate with scotch brite, and 600 grit. Carb checked to be sure I was getting WOT. Didn’t seem to make much of a difference.

Final check I did, since the lower plug looked a little bit cleaner than the upper, ran it with the lower plug out, and was getting a bit of a mist of water out of the lower cylinder spraying on my hand.

Ah-haaa?

Given that the block/head should be square, with a new gasket installed, and the head bolts torqued to factory specs, I wouldn’t expect it to have a blown head gasket. Also the exhaust plate was taken off, cleaned, inspected during the refresh. No signs of pitting/holes at the time. New gasket was installed with a light coat of 3M 847.

Im at a loss for where the water may be coming from, short of a crack in either the block/head that wasn’t apparent. My

Only other thought is it possibly normal for that cylinder to pull water up through the exhaust ports when there’s no pressure from the combustion process pushing it out?

Sorry for the novel length post, but I thought it’s best to get all the facts right out on the table.

Thanks!