runninfarmer

Petty Officer 2nd Class

- Joined

- Jun 28, 2012

- Messages

- 140

Hi All,

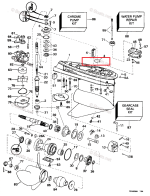

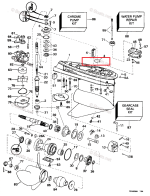

I'm in the process of disassembling a Johnson/Evinrude 150 60 degree gearcase so that I can replace all bearings, seals, and a couple gears. I need some help please with the pinion bearing. Removal looks straightforward, but I want all my ducks in a row. Since this is a '95 model, it doesn't have a retaining screw holding the bearing in place, but a retaining ring that looks easy enough to pull out (pic of diagram attached). Does it need to be pulled out the bottom and can it be reused? I have the manual, but mine is for the '91-'92 model years which had retaining screws. Everything else is the same. I'm planning to use a threaded rod with a socket to pull the bearing up out the top. Appreciate any info!

I'm in the process of disassembling a Johnson/Evinrude 150 60 degree gearcase so that I can replace all bearings, seals, and a couple gears. I need some help please with the pinion bearing. Removal looks straightforward, but I want all my ducks in a row. Since this is a '95 model, it doesn't have a retaining screw holding the bearing in place, but a retaining ring that looks easy enough to pull out (pic of diagram attached). Does it need to be pulled out the bottom and can it be reused? I have the manual, but mine is for the '91-'92 model years which had retaining screws. Everything else is the same. I'm planning to use a threaded rod with a socket to pull the bearing up out the top. Appreciate any info!