Chris in Utah

Seaman

- Joined

- Sep 25, 2019

- Messages

- 57

Thanks Sam, that’s encouraging. I keep finding things to fix, and while the transom doesn’t leak much, I figure while I have the boat turned turtle I may as well take care of it.

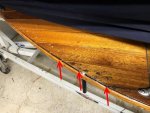

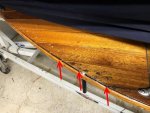

That said, let me see if I can bring us up to speed on where I’m at. I had to fix some decking damage and a rub rail that was pulling away.

Keel work now... but I’ve got to take a computer break for a bit before we get into that

That said, let me see if I can bring us up to speed on where I’m at. I had to fix some decking damage and a rub rail that was pulling away.

- After unscrewing the rub rail, I treated the damaged decking and associated screw holes with CPES dispensed from a small syringe.

- A couple days later I mixed two part epoxy with some mahogany sawdust and fumed silica (remember your respirator) to the consistency of peanut butter. I used a syringe to inject the epoxy into the screw holes and cracks on the damaged deck section and the rub rail screw holes.

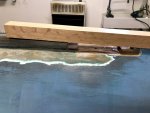

- I ran a ratchet strap stem to stern and then roped a 2x4 to it, resting on the deck. This let me use a set of clamps to squeeze tight the deck planking that had split once I had the epoxy injected in the cracks. (Actually set this up prior to mixing the two part epoxy.) The rope had more give than I’d like, but it worked ok. Aluminum foil placed between the rub rail and the deck planks so we didn’t accidently epoxy the rail down.

- Then I re-drilled the screw hole for the rub rail using a tapered bit and screwed it back down with mostly original hardware (had to replace four screws). Sorry I forgot to get a photo before I turned the boat over. There’s video, but I haven’t got it up to YouTube yet.

- Then I made up a couple cradles for mid and foredecks. Harbor Freight furniture dollies let me move it around. (Stern is held on a dolly also, via motor mount section of the transom. I’ll have to change that support before I re seal the transom.)

- To actually flip it, I rigged a couple block and tackle pulleys for the stern attached via a couple waterski rope attachment eye bolts my boat conveniently has on the transom. And an engine hoist at the bow. I had to reposition the engine hoist once to finish getting the trailer out, but the bow rested easily on the trailer and some seat cushions while I moved the hoist.

Keel work now... but I’ve got to take a computer break for a bit before we get into that