pekstrom

Chief Petty Officer

- Joined

- Dec 31, 2015

- Messages

- 490

Hi everyone,

I recently aquired a 1963 Merc350 that needs lots of help. I got it real cheap so I figured I'll have a project for a year or two. The biggest issue is that it seems stuck. If I put a wrench on the flywheel nut, It doesn't turn. Well, it acts as if something slips on the inside, on step, if that makes sense. But it doesn't feel right. And I can't turn it any further. I can just go back and forth one step. So I am working on getting it opened up to see what's going on on the inside.

I'm having some trouble getting the flywheel off. The nut comes off but I haven't been able to pull the wheel off yet. I got me a wheel puller but the flywheel is stuck good on the shaft. I've been spraying Blaster PB on it for a while now.

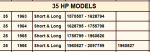

My fear is that I'll need a new engine block. I've read somewhere that the 1963 models had some differences from the 1964 and later models. They seem to have the same part numbers though. Does anyone here know if a 1964 block would fit on a 1963 model? It is in the 1571114 - 1812753 serial number range. One would assume if another block came off of an engine in the same range, it should fit?

Thanks in advance for any info.

I recently aquired a 1963 Merc350 that needs lots of help. I got it real cheap so I figured I'll have a project for a year or two. The biggest issue is that it seems stuck. If I put a wrench on the flywheel nut, It doesn't turn. Well, it acts as if something slips on the inside, on step, if that makes sense. But it doesn't feel right. And I can't turn it any further. I can just go back and forth one step. So I am working on getting it opened up to see what's going on on the inside.

I'm having some trouble getting the flywheel off. The nut comes off but I haven't been able to pull the wheel off yet. I got me a wheel puller but the flywheel is stuck good on the shaft. I've been spraying Blaster PB on it for a while now.

My fear is that I'll need a new engine block. I've read somewhere that the 1963 models had some differences from the 1964 and later models. They seem to have the same part numbers though. Does anyone here know if a 1964 block would fit on a 1963 model? It is in the 1571114 - 1812753 serial number range. One would assume if another block came off of an engine in the same range, it should fit?

Thanks in advance for any info.