Re: 1969 Larson - Big Project

(July 6th Update)

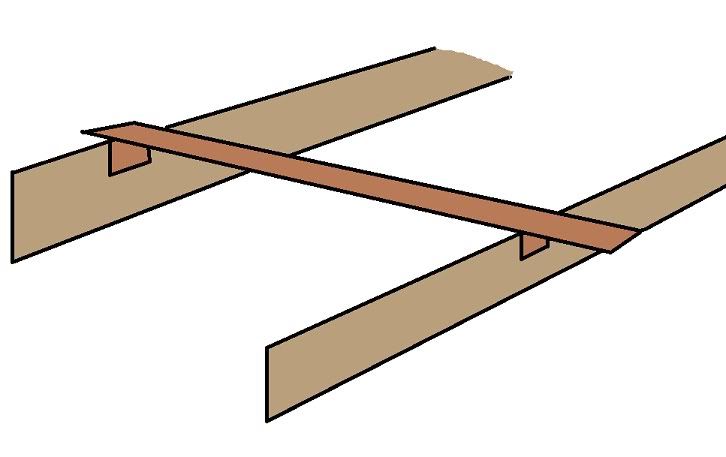

Now to put the thing in! A few posts back Wood introduced me to a much easier method of leveling out my stringers for gluing in. Check it if you missed it. I stuck with my current method for getting my mid-stringer in place...

After that, glued in with PB...

Sorry about the pic quality! My digital camera is having focus issues. Back to the cam-phone, I think.

An update on supplies used for those trying to learn, like me! Thus far, I've completed my tear down and sanding, patches some holes, completed my transom, soaked and glued in my stringers. Here's my materials list thus far:

5.3 gallons resin

4 yards CSM

2 yards 1708

EPIC sanding and grinding discs

Plenty of baby powder

10 or so quart pails (you can re-use)

4 qts chopped strand

10 quarts cabosil

108 latex gloves (acetone eats them up)

1.2 gallons of acetone

2 tyvec suits (worthless)

4 air filters

Numerous chip brushes

8 4" rollers

This also doesn't count my tool upgrades and additions. I'll probably make a list of those when I'm done. To be fair, as far as my glass mat count goes, a good portion of that is still in the scrap pile. I suspect I ordered plenty! My shipment of pour-in foam arrived today, which I can't wait to play with! No doubt I'm going to have to order more resin.

IN CASE ANYONE MISSED IT: PB USES UP AN EPIC AMOUNT OF RESIN! I'll use more resin making PB than I will anything else!

ALSO, if you have to replace your deck, if you can, make DARN sure you mark out where your deck sits on the hull!!!!!! For many reasons, I didn't have the option of doing this. It's going to be a PITA, but I'm more or less going to have to guesstimate my deck height and level. I took a ton of pics during tear-down, as well as measurements, but it definitely isn't the same as marking it out on the hull. Just do it!

Dead soldier...

My lofty goal for the weekend: Stringers, bulkheads, and bilge cut to height and glassed in. Maybe doing a deck template.

NOT.