Propellerhead

Petty Officer 3rd Class

- Joined

- Nov 15, 2013

- Messages

- 94

Re: 1969 Sea Ray SRX Pachanga Build Thread

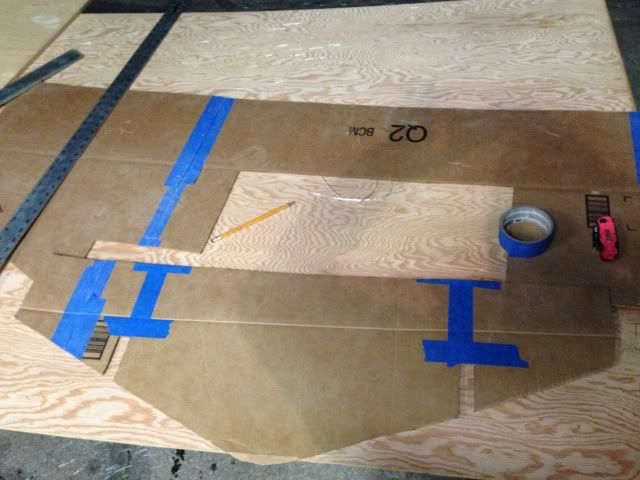

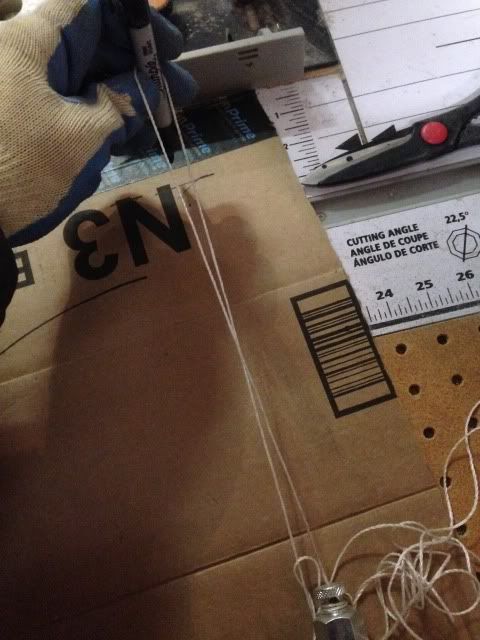

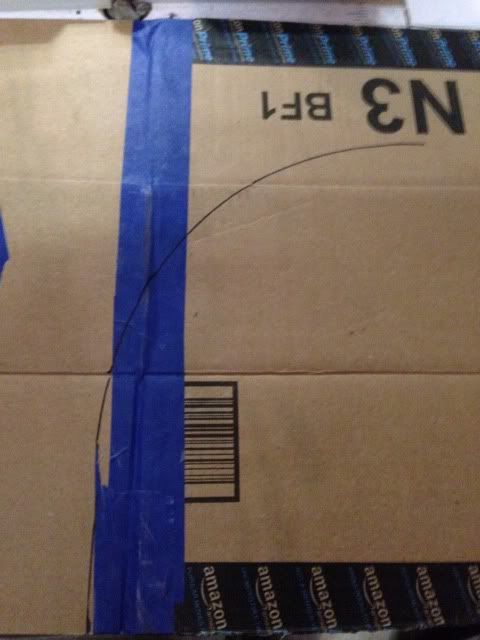

Thanks. Yeah I've done a ton of research on doing it right. It is a big job, that's for sure. Unfortunately marine ply was way out of my budget, but everything I saw indicated that AC would do just fine given the right treatment. I would have loved to keep the parts boat intact, but unfortunately the space just wasn't available. Thanks for the tips, there's more fun to come!

Thanks. Yeah I've done a ton of research on doing it right. It is a big job, that's for sure. Unfortunately marine ply was way out of my budget, but everything I saw indicated that AC would do just fine given the right treatment. I would have loved to keep the parts boat intact, but unfortunately the space just wasn't available. Thanks for the tips, there's more fun to come!