Re: 1969 Sea Ray SRX Pachanga Build Thread

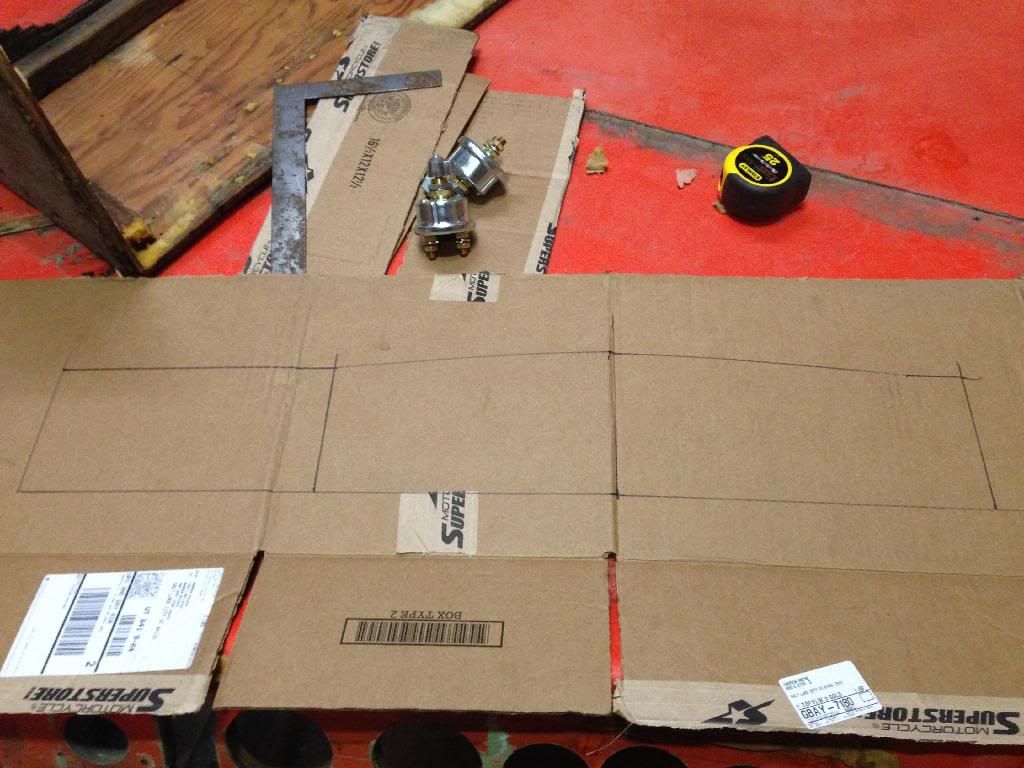

Well, this will be a short update. I was able to get a little work done this weekend, but it's frigidly cold and I'm feeling under the weather, so this is what I could accomplish. I had some help today, so while my buddy was doing other things, I decided to measure the boat for the x-dimension. Basically, with the new transom in place, I need to measure everything out so I can cut the hole correctly for the outdrive to pass through. The first thing you have to do is find the exact center of the boat, then you have to figure out the x-dimension, which is the vertical position of the engine crankshaft centerline. Everything is positioned based off of this measurement.

We found the boat centerline by tying a sharpie to a piece of string that's a consistent length. It doesn't really matter what length it is, as long as it's slightly more that half the width of the boat. We then drew an arc on the transom by holding the string on a specific point on the side of the hull (we used one of the outboard chines). Once this is accomplished on both sides, as you can see in the picture, where the arcs intersect on the top and bottom of the transom are two points that are in the exact center of the hull. After that, it's as simple as taking a straight edge and connecting the two points with a line. This is the centerline.

Now it's time to find the x-dimension. You can look this up in the Mercruiser manuals, but basically what it says is that the stock x-dimension is located at 13 9/16 inches from the bottom of the hull. However, you can modify this number based on what the intended purpose is for your boat.

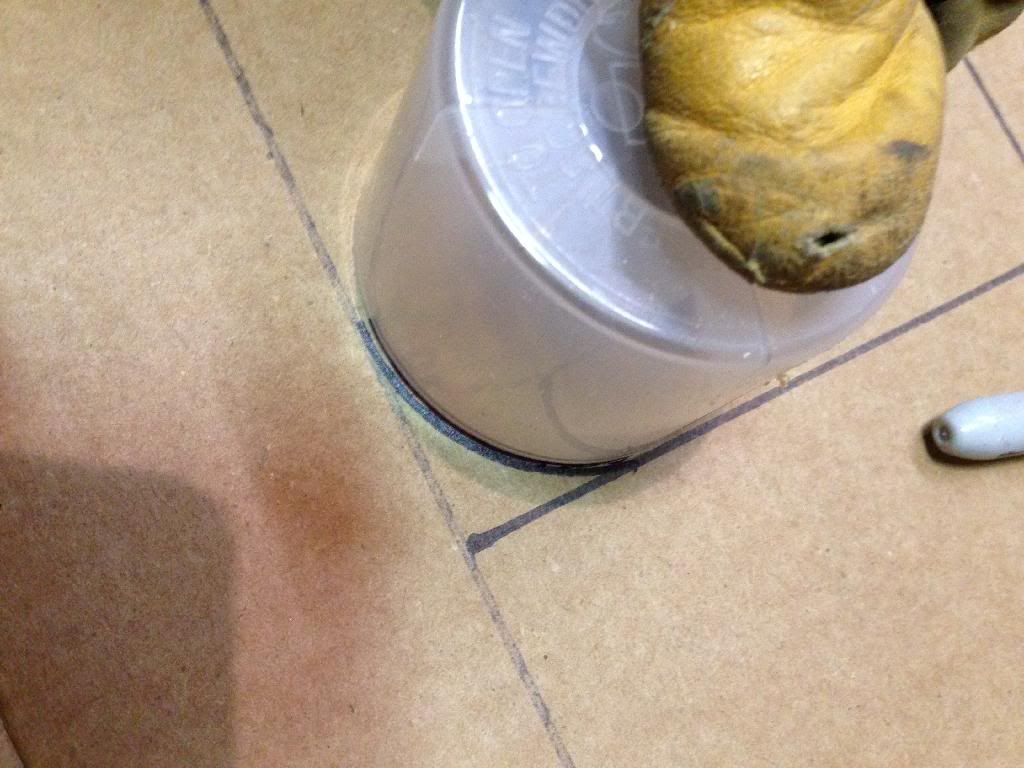

I set my square to 13 9/16 inches.

I had to jack the boat up off the trailer to get my square under the hull.

We put a straight edge under the hull and used the square to measure up 13 9/16 inches. You have to use a straight edge off of the hull because the transom is at an angle. Since it isn't 90 degrees you can just measure up from the bottom. But anyhow, it worked and I marked the x-dimension on the transom.