Hello all!

I'm Chris and I'm not only new to this forum but I'm also new to boating in general. So new that I've never even been on a boat!

My life consisted of building cars and motorcycles - mostly European stuff. I figured this whole boat thing would be a nice change and some new territory to explore. So I got my first boat. It was really a fluke, and just a "right place at the right time" incident.

So without further ado:

Here is my new toy!

Now I am new to boating, but I have played around with fiberglass before. What I mean is that I have basic knowledge of wetting out and laying up a few layers of non-structural stuff. Mostly custom car audio speaker/amplifier enclosures. I have been reading through many builds on this forum, and trying to get a sense of how things are generally done on marine applications. So far - so good.

The reason I started this thread is because I want to do a cosmetic restoration on my boat. The color is horrible and there are a few problem areas that I'd like to address.

Have a look and please feel free to give me some guidance on the propper methods of fixing the issues.

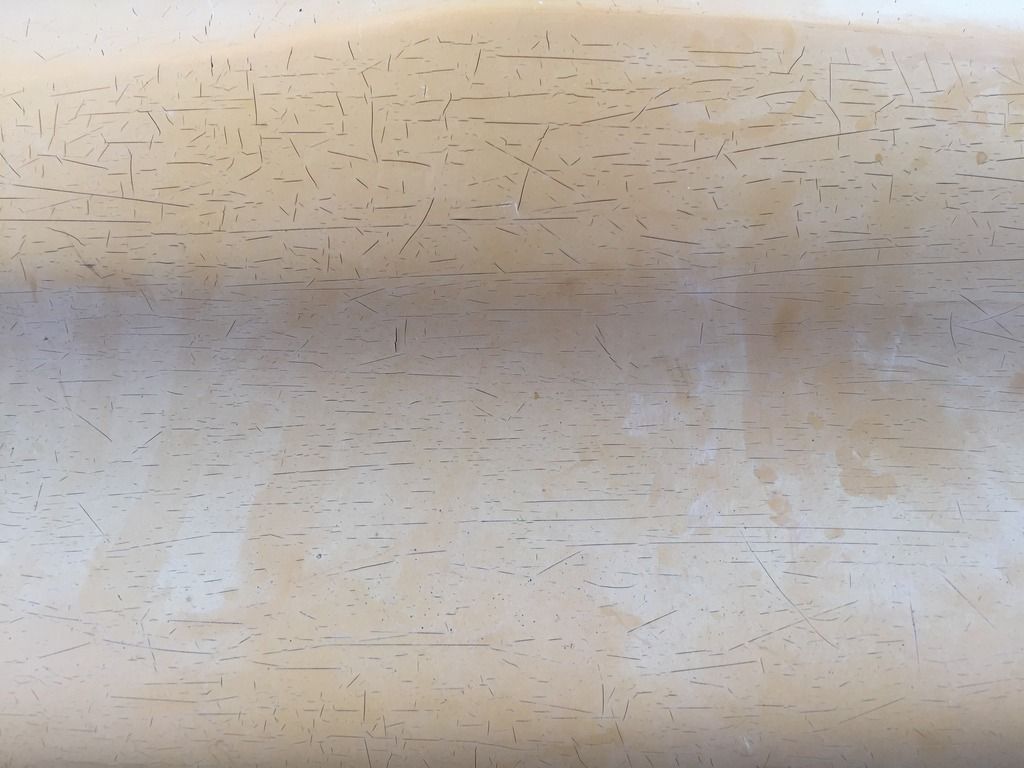

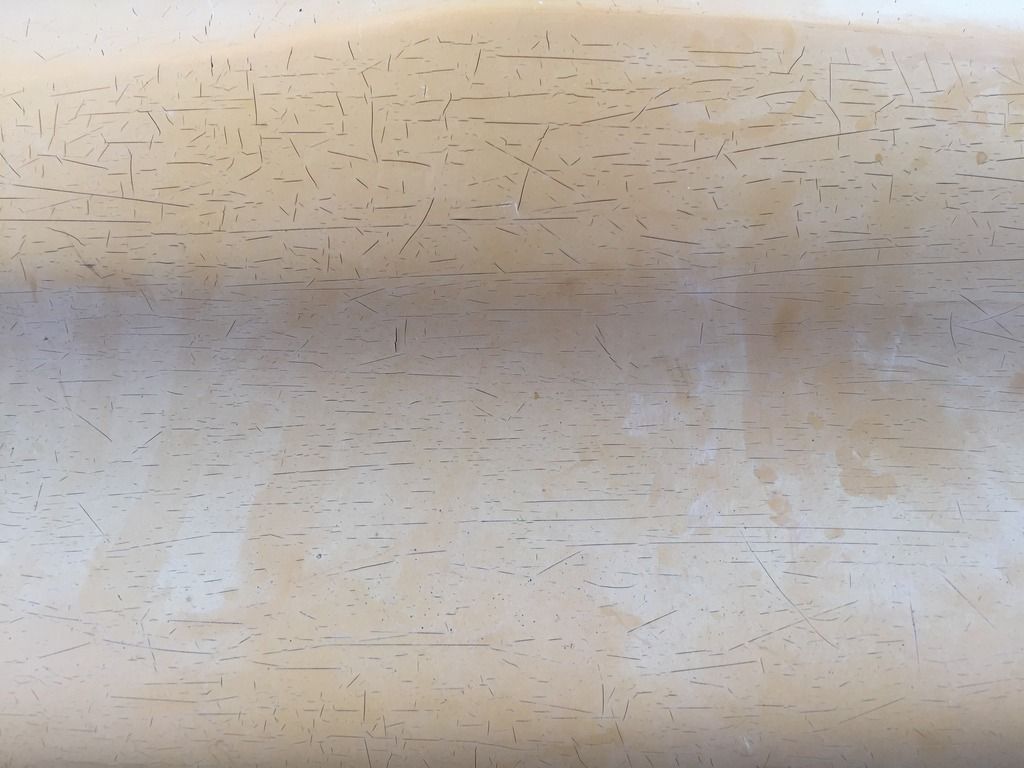

Spider cracks along the port side

Gelcoat cracked off with dry fibers exposed

More gelcoat cracked off with more fibers poking out

Generally poor sunbaked and cracked gelcoat

Also a bunch of unnecessary screw holes

Overall this thing has seen better days, but I just couldn't resist the style.

As you can see most of the bad spots are all on the topside. I'm guessing repairs to this section would be similar to working on a corvette of similar vintage? Or am I way off on that assumption?

I'm Chris and I'm not only new to this forum but I'm also new to boating in general. So new that I've never even been on a boat!

My life consisted of building cars and motorcycles - mostly European stuff. I figured this whole boat thing would be a nice change and some new territory to explore. So I got my first boat. It was really a fluke, and just a "right place at the right time" incident.

So without further ado:

Here is my new toy!

Now I am new to boating, but I have played around with fiberglass before. What I mean is that I have basic knowledge of wetting out and laying up a few layers of non-structural stuff. Mostly custom car audio speaker/amplifier enclosures. I have been reading through many builds on this forum, and trying to get a sense of how things are generally done on marine applications. So far - so good.

The reason I started this thread is because I want to do a cosmetic restoration on my boat. The color is horrible and there are a few problem areas that I'd like to address.

Have a look and please feel free to give me some guidance on the propper methods of fixing the issues.

Spider cracks along the port side

Gelcoat cracked off with dry fibers exposed

More gelcoat cracked off with more fibers poking out

Generally poor sunbaked and cracked gelcoat

Also a bunch of unnecessary screw holes

Overall this thing has seen better days, but I just couldn't resist the style.

As you can see most of the bad spots are all on the topside. I'm guessing repairs to this section would be similar to working on a corvette of similar vintage? Or am I way off on that assumption?