Fatguynalittleboat...

Seaman

- Joined

- May 12, 2013

- Messages

- 62

I?ve been trouble shooting some issues for some time now with my motor. It runs strong!!!

The issue I?m having is with it bucking/misfiring at certain intervals running through its cycle from slow idle-to wide open throttle. Initially I wasn?t aware that the CD2 motor was a coil and sensor motor so I was thinking I?d need to adjust the points for timing adjustments.

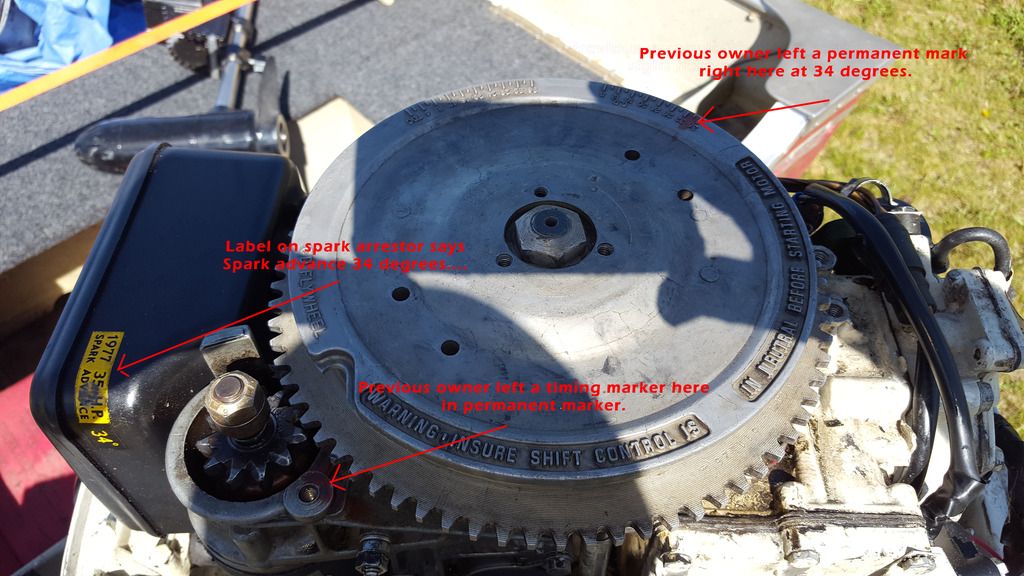

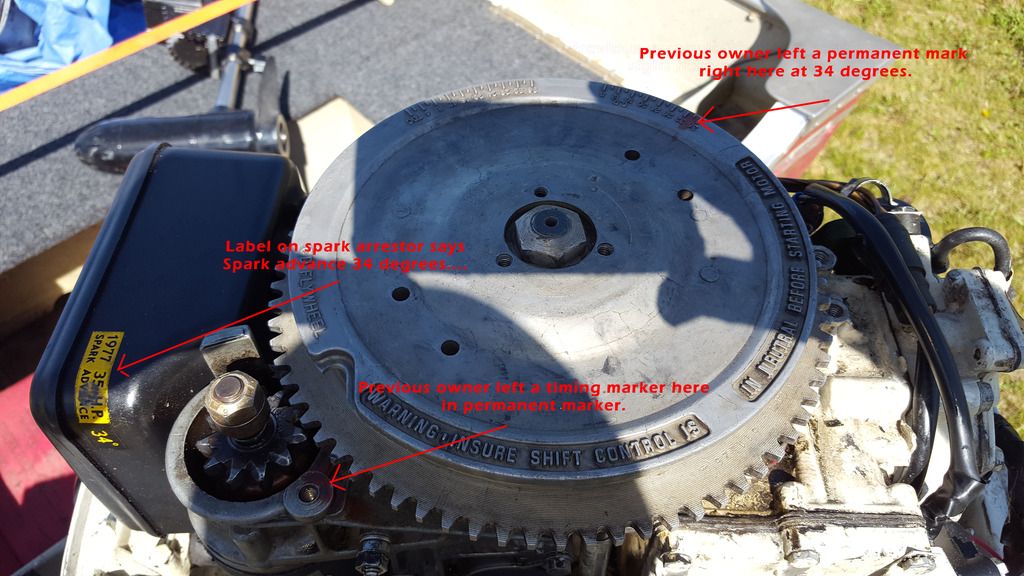

This motor starts up every time but I need to feather the throttle to run nice and smooth?.When I go through the range of throttle up to wide open, it will sputter?.but not loose power. There?s an issue with timing somewhere. The P.O. set a timing marker on the starter motor bracket with permanent marker. There is also another marking with the same color permanent marker on the flywheel at the 34 degree marking. There is a yellow sticker on the spark arrestor which indicates that the advance timing should be set at 34 Degrees W.O.T.

The manual says my tune up specs should be at 30 degrees W.O.T?.Which I?m inclined to believe. I just bought a new timing light today and I would like to see if my motor is timed properly.

The manual says there is a locking nut and an adjustment screw for this procedure,(advance/retard timing), but the photo in the manual is poor and I can?t see where these screws are. Will someone point them out to me?

Also....

Is 30 Degrees the proper timing for this motor?

Lots of pictures below....

The issue I?m having is with it bucking/misfiring at certain intervals running through its cycle from slow idle-to wide open throttle. Initially I wasn?t aware that the CD2 motor was a coil and sensor motor so I was thinking I?d need to adjust the points for timing adjustments.

This motor starts up every time but I need to feather the throttle to run nice and smooth?.When I go through the range of throttle up to wide open, it will sputter?.but not loose power. There?s an issue with timing somewhere. The P.O. set a timing marker on the starter motor bracket with permanent marker. There is also another marking with the same color permanent marker on the flywheel at the 34 degree marking. There is a yellow sticker on the spark arrestor which indicates that the advance timing should be set at 34 Degrees W.O.T.

The manual says my tune up specs should be at 30 degrees W.O.T?.Which I?m inclined to believe. I just bought a new timing light today and I would like to see if my motor is timed properly.

The manual says there is a locking nut and an adjustment screw for this procedure,(advance/retard timing), but the photo in the manual is poor and I can?t see where these screws are. Will someone point them out to me?

Also....

Is 30 Degrees the proper timing for this motor?

Lots of pictures below....