Hello,

Just signed up on the forums today but I have been lurking and reading for several months now in prep from my project.

I just aquired a 1980 chrysler striper with a 55hp chrysler outboard and trailer and it needs work. The boat was sitting uncovered and unprotected for the last 8 years.

The Good:

The Hull is solid and in great shape. Some minor chips and dings but no holes or cracks. The engine started right up and pulled water from a tub also shifted fwd/rev/neutral with no issues. The guages, lights and switches are all present but the wiring is a mess.

The bad:

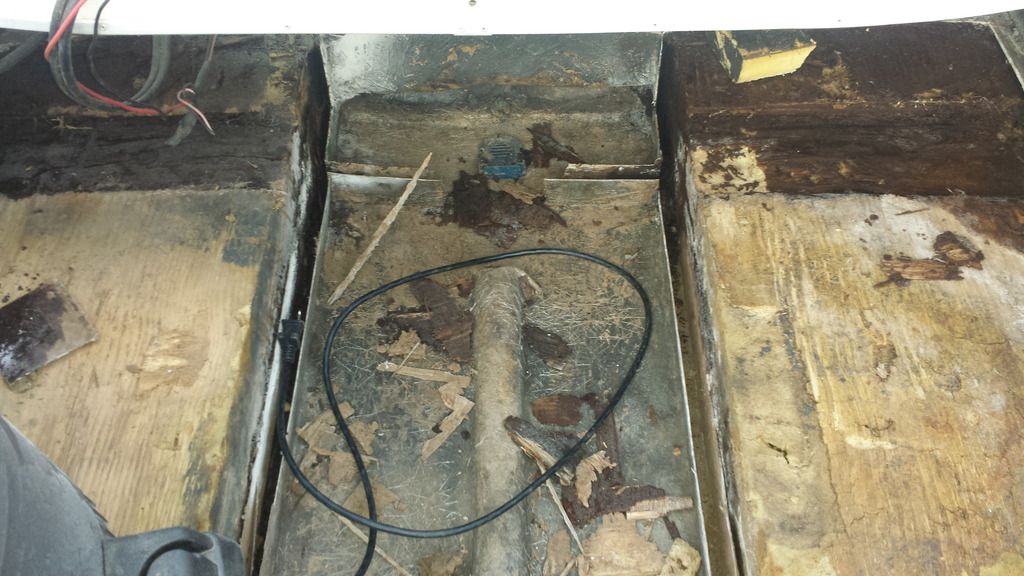

The floor, stringers,foam and transom. Floor was previously cut out. Stringer are all mush nothing left. The foam is water logged. The transom is still intact but the wood is soft and rotten.

I have stared the cleanout of the stringers and the foam but i am hoping there is someone around familiar with this boat who can tell me if it is possible to replace the transom without splitting the shell.

I have no experience with boat restoration but I have some carpentry, electrical and automotive restoration experience. I also have nothing but free time. I have been doing alot of online research about the job ahead of me and I feel everything I need to do is well within my skill set.

I will post all the pictures I have taken once I can get to a computer. I would like tro avoid splitting the hull if at all possible and any input on my project will be welcomed.

Just signed up on the forums today but I have been lurking and reading for several months now in prep from my project.

I just aquired a 1980 chrysler striper with a 55hp chrysler outboard and trailer and it needs work. The boat was sitting uncovered and unprotected for the last 8 years.

The Good:

The Hull is solid and in great shape. Some minor chips and dings but no holes or cracks. The engine started right up and pulled water from a tub also shifted fwd/rev/neutral with no issues. The guages, lights and switches are all present but the wiring is a mess.

The bad:

The floor, stringers,foam and transom. Floor was previously cut out. Stringer are all mush nothing left. The foam is water logged. The transom is still intact but the wood is soft and rotten.

I have stared the cleanout of the stringers and the foam but i am hoping there is someone around familiar with this boat who can tell me if it is possible to replace the transom without splitting the shell.

I have no experience with boat restoration but I have some carpentry, electrical and automotive restoration experience. I also have nothing but free time. I have been doing alot of online research about the job ahead of me and I feel everything I need to do is well within my skill set.

I will post all the pictures I have taken once I can get to a computer. I would like tro avoid splitting the hull if at all possible and any input on my project will be welcomed.