MrHProblems

Seaman Apprentice

- Joined

- Jun 2, 2025

- Messages

- 34

I recently acquired this 1986 Four Winns Horizon 190 with a Mercruiser 230 V8 in it.

The motor runs and sounds good at idle but it feels underpowered, only goes up to 3,000 rpms and 30mph at WOT under load.

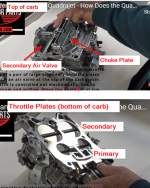

I noticed the throttle plates/butterflies don't open at all when I move the throttle. I disconnected the throttle cable so I would have full range of throttle abilities and they don't open that way either. I can use my finger and easily move them fully vertical though.

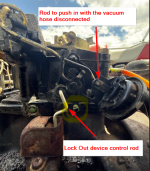

Here is a pic from what I believe is the throttle shaft(circled) with nothing connected to it.

I cant find a diagram that makes any sense online for what I am missing here.

*Crossposted*

The motor runs and sounds good at idle but it feels underpowered, only goes up to 3,000 rpms and 30mph at WOT under load.

I noticed the throttle plates/butterflies don't open at all when I move the throttle. I disconnected the throttle cable so I would have full range of throttle abilities and they don't open that way either. I can use my finger and easily move them fully vertical though.

Here is a pic from what I believe is the throttle shaft(circled) with nothing connected to it.

I cant find a diagram that makes any sense online for what I am missing here.

*Crossposted*