I'm pretty sure I messed up on the catalyzing of the resin, this time around, in 2011 I had no issues and it was colder too.

It was 72F the day I did this (this past Wednesday).

I mixed as per the instructions (68F) @ 1.5% (15 min working time, 45 minutes gel as per the sheet)..

The first CSM layer (the one with the tape) was still soft after 2hrs, so I heated the outside with a 500W halogen 2' away 30m later it had kicked off and I removed the tape. Before the 500W using a laser temp gun the surrounding area was only 62F.

I tried to do the outside with the halogen on but it seemed to be kicking off quick so I stupidly reduced to 1.25% and turned the halogen off. It dropped to 60F that night. The next morning was very sticky, I applied a 2% batch with air-dry and that kicked off.

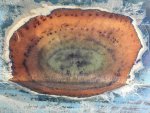

Soft "pucks" left in mixing cups:

I was only mixing small portions (4oz or so at a time). It seemed to gel in the "pot", but the pucks are hard on the outside and throwing them VERY hard on the ground just cracks them. The inside is like rubber! Even hitting with a hammer just bounces off. I can with my finger "push" the bottom of the puck like a superball.

What do I do?! IF I redo this, How do I sand back to where I started?! I think it'll be a huge mess, but I'm not sure it's in a good state now. The lamination's on the boat seem kicked off and hard. Jez. YES that's a screw driver easily pushed into the cured "rubber resin"

I ended up with: (1.5oz CSM was used)

Inside: 1 CSM, 3 x 1708.

Outside: 1 CSM, 1 x 1708, 3 x CSM

The strake is going to be a real hassle to get even again.

Ben

It was 72F the day I did this (this past Wednesday).

I mixed as per the instructions (68F) @ 1.5% (15 min working time, 45 minutes gel as per the sheet)..

The first CSM layer (the one with the tape) was still soft after 2hrs, so I heated the outside with a 500W halogen 2' away 30m later it had kicked off and I removed the tape. Before the 500W using a laser temp gun the surrounding area was only 62F.

I tried to do the outside with the halogen on but it seemed to be kicking off quick so I stupidly reduced to 1.25% and turned the halogen off. It dropped to 60F that night. The next morning was very sticky, I applied a 2% batch with air-dry and that kicked off.

Soft "pucks" left in mixing cups:

I was only mixing small portions (4oz or so at a time). It seemed to gel in the "pot", but the pucks are hard on the outside and throwing them VERY hard on the ground just cracks them. The inside is like rubber! Even hitting with a hammer just bounces off. I can with my finger "push" the bottom of the puck like a superball.

What do I do?! IF I redo this, How do I sand back to where I started?! I think it'll be a huge mess, but I'm not sure it's in a good state now. The lamination's on the boat seem kicked off and hard. Jez. YES that's a screw driver easily pushed into the cured "rubber resin"

I ended up with: (1.5oz CSM was used)

Inside: 1 CSM, 3 x 1708.

Outside: 1 CSM, 1 x 1708, 3 x CSM

The strake is going to be a real hassle to get even again.

Ben