offshore79

Seaman Apprentice

- Joined

- Jul 22, 2011

- Messages

- 30

Hi all, It's my first post.

I've been reading alot of posts of similar issues and then some and I still dont have a solution to my problem.

What I have and what I've done.

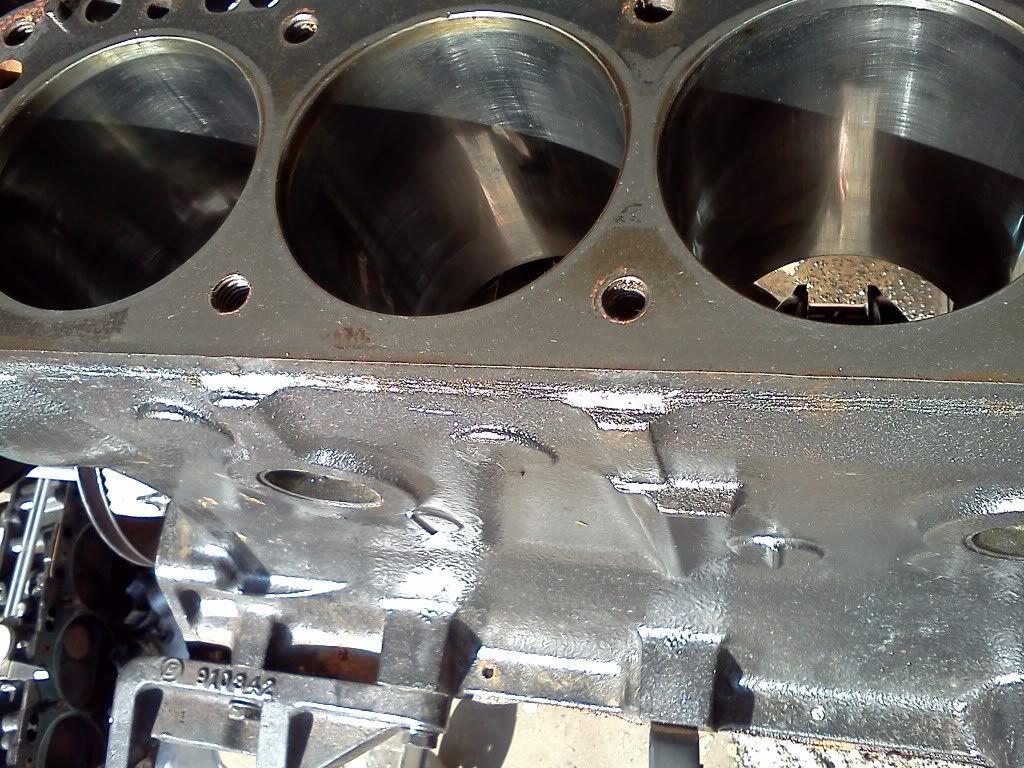

I bought a fixer upper 19 baja with a bad OMC 3.0 engine. The head was cracked and the cylinders were rusted. The inside of the engine was like new.

I had it bored .030 to clean up the pitting and deck surfaced to clean up a divet(I think the previous owner dropped the head on it). New pistons and rings. Pistons were snug but at the bottom of the tolerance. Ring gap right on the money.

Used but very good replacement 3.0 (correct one) head.

Everything torqued to spec.

New gaskets and seals all around

Valve lash adjusted.

New coil, points, condenser, wires. Point gap.019, fire order 1342, timing 1 deg btdc.

Thermostat - tested - functional.

Rebuilt carb. Adjusted choke.

Plenty of fuel (new) and new fuel filter.

It starts, idles well, comes up to 175 deg, with oil pressure at about 35. I let it run for about 2 minutes at idle, picked it up to about 1500rpm, runs for awhile 3-5 minutes and then starts to stumble and then drops off. I backed off on the throttle and it died.

I thought timing, carberator, valve adjustment. Checked and rechecked everything.

Resitor wire seems fine also.

The only things I notice is that it runs slightly less then perfect...when just started.

I am so out of ideas. Thoughts?

Thanks

Offshore79

I've been reading alot of posts of similar issues and then some and I still dont have a solution to my problem.

What I have and what I've done.

I bought a fixer upper 19 baja with a bad OMC 3.0 engine. The head was cracked and the cylinders were rusted. The inside of the engine was like new.

I had it bored .030 to clean up the pitting and deck surfaced to clean up a divet(I think the previous owner dropped the head on it). New pistons and rings. Pistons were snug but at the bottom of the tolerance. Ring gap right on the money.

Used but very good replacement 3.0 (correct one) head.

Everything torqued to spec.

New gaskets and seals all around

Valve lash adjusted.

New coil, points, condenser, wires. Point gap.019, fire order 1342, timing 1 deg btdc.

Thermostat - tested - functional.

Rebuilt carb. Adjusted choke.

Plenty of fuel (new) and new fuel filter.

It starts, idles well, comes up to 175 deg, with oil pressure at about 35. I let it run for about 2 minutes at idle, picked it up to about 1500rpm, runs for awhile 3-5 minutes and then starts to stumble and then drops off. I backed off on the throttle and it died.

I thought timing, carberator, valve adjustment. Checked and rechecked everything.

Resitor wire seems fine also.

The only things I notice is that it runs slightly less then perfect...when just started.

I am so out of ideas. Thoughts?

Thanks

Offshore79

Last edited: