jc55

Senior Chief Petty Officer

- Joined

- Nov 3, 2006

- Messages

- 665

This is my absolute dream boat. I love to do this type of work. So, just to clear the air, I knew what I was getting into and it still makes economic sense...and I ain't scared!  With soft floors, I equate this to never being able to afford this boat otherwise, with close to the same repair investment as a $300 boat. At least comparable.

With soft floors, I equate this to never being able to afford this boat otherwise, with close to the same repair investment as a $300 boat. At least comparable.

Still waiting to bring the Sport Craft home on clear roads to finish her assembly. This current boat is not a priority and I kind of promised the wife I'd not go in over my head just yet.

Some history, this is a Florida boat, used commercially for a time with heavy sonar equipment carried on it's decks. Salt water all it's life, never covered or indoors as far as I know. It was 35 miles off shore last summer. I feel the stringers through the sags in the deck. They "feel solid", and I have the stringer layout. They are all short stringers and bulkheads(no long pieces, grid design)

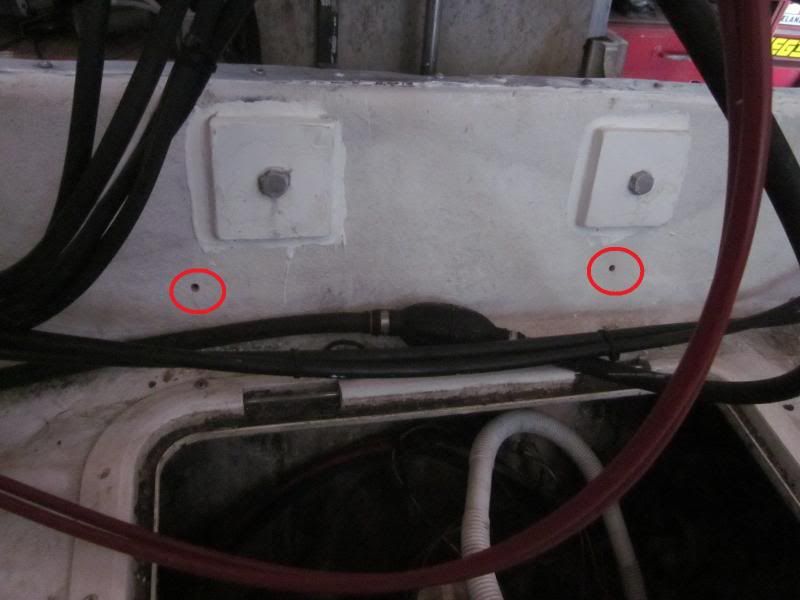

The transom...

The jack plate bolts have spacers. Obviously home made. The bent trim on the transom is from tilting the motor (200hp) forward when the jack plate is too low. It's all sealed with 5200 and paint. The previous owner was completely upfront and wasn't trying to hide anything.

See the bow? My finger denotes the depth. The outside of the transom at the deck joint (at bottom of jack plate)is straight.

Part of me wants to run a heavy duty aluminum C-channel across the transom for a season...

If the transom is wet, it should be salt water. Thoughts?

Still waiting to bring the Sport Craft home on clear roads to finish her assembly. This current boat is not a priority and I kind of promised the wife I'd not go in over my head just yet.

Some history, this is a Florida boat, used commercially for a time with heavy sonar equipment carried on it's decks. Salt water all it's life, never covered or indoors as far as I know. It was 35 miles off shore last summer. I feel the stringers through the sags in the deck. They "feel solid", and I have the stringer layout. They are all short stringers and bulkheads(no long pieces, grid design)

The transom...

The jack plate bolts have spacers. Obviously home made. The bent trim on the transom is from tilting the motor (200hp) forward when the jack plate is too low. It's all sealed with 5200 and paint. The previous owner was completely upfront and wasn't trying to hide anything.

See the bow? My finger denotes the depth. The outside of the transom at the deck joint (at bottom of jack plate)is straight.

Part of me wants to run a heavy duty aluminum C-channel across the transom for a season...

If the transom is wet, it should be salt water. Thoughts?