(90 hp) E90FPLEEC - Runs fine at idle speeds. But when trying to run above 3000 rpm, motor stalls after about 5 minutes. Like it's not getting gas. When it stalls, only thing I do is pump the primer bulb a couple of times, wait about 3-4 minutes and it starts back up. Now the other side of the this problem, doesn't do it all the time!

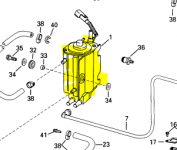

All suggestions? Everyone around me thinks fuel pump needs rebuilt. Unable to find rebuild kit or fuel pump. ( 5004454 Fuel Pump Kit)

All suggestions? Everyone around me thinks fuel pump needs rebuilt. Unable to find rebuild kit or fuel pump. ( 5004454 Fuel Pump Kit)