The tacho hasn’t worked since I own the boat, while I’m fixing some other things this is another project I want to fix up but I have run into issues and I’m not sure if it isn’t working because of a bad setup or something broken. Into the back of the gauge on the send pin I have both a grey wire and a brown and white wire. There is also a light brown wire with blue stripe that isn’t connected to anything. At the remote control (outside the unit) I have a green / white, red, brown, blue white.

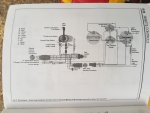

initially I brought a generic gauge and did a direct swap but that didn’t change anything, my manual listed a tacho converter module which I can’t see so I brought one of those, but looking to install it the colours don’t line up.

So now I have the original tacho in unknow condition, a new generic tacho and the tacho converter module with coloured wiring which doesn’t line up with what my manual says (manual says green is the tach signal)

What is the output am I looking for to identify which is the signal wire? Is there some voltage or frequency I can identify with a multimeter? I’d rather not just start trying random wires and fry either the tacho or the converter module.

Yes the outboard is charging the battery with the rectifier putting out 14v

initially I brought a generic gauge and did a direct swap but that didn’t change anything, my manual listed a tacho converter module which I can’t see so I brought one of those, but looking to install it the colours don’t line up.

So now I have the original tacho in unknow condition, a new generic tacho and the tacho converter module with coloured wiring which doesn’t line up with what my manual says (manual says green is the tach signal)

What is the output am I looking for to identify which is the signal wire? Is there some voltage or frequency I can identify with a multimeter? I’d rather not just start trying random wires and fry either the tacho or the converter module.

Yes the outboard is charging the battery with the rectifier putting out 14v