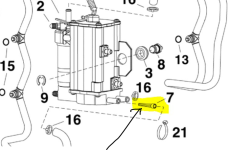

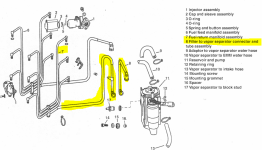

engine dying with no codes is indicative of a fuel flow problems either at the low side lift pump or lack of high pressure fuel to the injectors

2 things NOT monitor in the ETEC emms anyway...likely the same in FICHT

here is a video on TPS adjustments possibly similar to the FICHT world

to test fuel injection remove a spark plug(s) and test one or all injectors by insering a paper strip in the cylinders are activate the inj with EV diag to pulse some fuel.

if injectors sprayed paper strips are dry.....injectors are not fed fuel or plugged up or simply not firing ( at least listen for clicks).

Open or shorted injectors would have generated fault codes so they are likely OK.

also check sparks with a automotive type gun ( on ETECs....

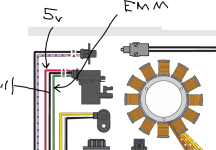

open air firing of plugs has been known to generate high EMF freq pulses which can mess up the EMM !!!

during the paper test above GROUND the plugs properly

you need all three fuel air and sparks !

you can vist the ETEC Board but

they will not answer FICHT questions you can nonetheless do searches on past trouble cases like yours for clues

www.etecownersgroup.com

keep us posted

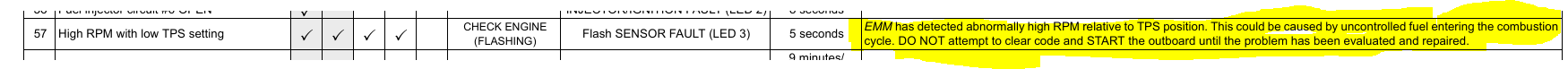

btw NOT TURNING OVER.... is another matter check neutral switch or any safety devices check all wiring etc.... some drastic fault codes MUST BE RESET (see manual)