i386

Captain

- Joined

- Aug 24, 2004

- Messages

- 3,548

I overheated my 33hp today. Engine slowed down while running at WOT. My first reaction was to grab the primer bulb but it was firm. Seconds later she stopped running. The cowl cover felt hot and when I opened the little door, white smoke poured out.

Back home I checked to see if the flywheel would turn freely and it did. Next I did a compression check on both cylinders. 60 psi top, 90 psi bottom. Top is low for sure. Bottom is about right if I recall correctly.

After that I pulled the head. All bolts broke free easily thank goodness. I can't tell by looking at the gasket if it failed. The top piston is clean as a whistle. The bottom one has some carbon on it. I'm thinking the gasket failed on the top cyl. and allowed the water to steam clean the piston. There is some slight scoring in both cyls. I don't know how much scoring, if any, is acceptable in a 44 year old engine.

Am I on the right track to install a new head gasket and re-check compression? I could hear and feel something not right in the water pump while moving the flywheel by hand. I expect at the very least for the impeller to be in peices.

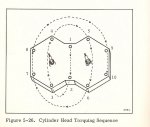

Any tips for getting a wrench solidly on that bottom head bolt? Should I use anti-seize when re-assembling? Which gasket sealer if any goes on the head gasket?

Thanks!

Back home I checked to see if the flywheel would turn freely and it did. Next I did a compression check on both cylinders. 60 psi top, 90 psi bottom. Top is low for sure. Bottom is about right if I recall correctly.

After that I pulled the head. All bolts broke free easily thank goodness. I can't tell by looking at the gasket if it failed. The top piston is clean as a whistle. The bottom one has some carbon on it. I'm thinking the gasket failed on the top cyl. and allowed the water to steam clean the piston. There is some slight scoring in both cyls. I don't know how much scoring, if any, is acceptable in a 44 year old engine.

Am I on the right track to install a new head gasket and re-check compression? I could hear and feel something not right in the water pump while moving the flywheel by hand. I expect at the very least for the impeller to be in peices.

Any tips for getting a wrench solidly on that bottom head bolt? Should I use anti-seize when re-assembling? Which gasket sealer if any goes on the head gasket?

Thanks!