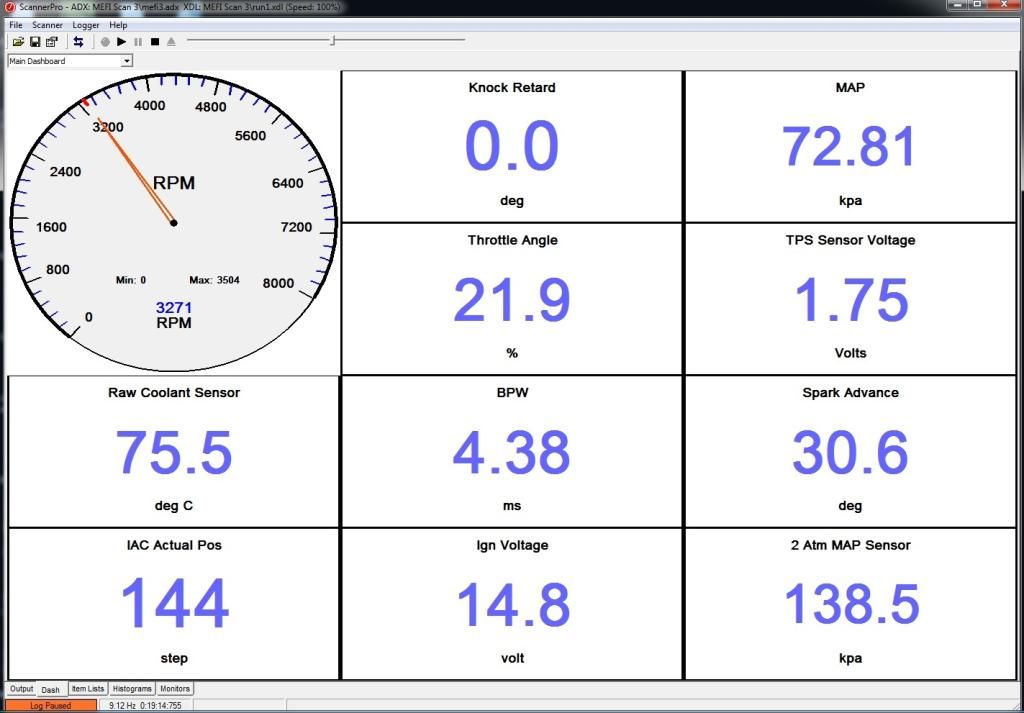

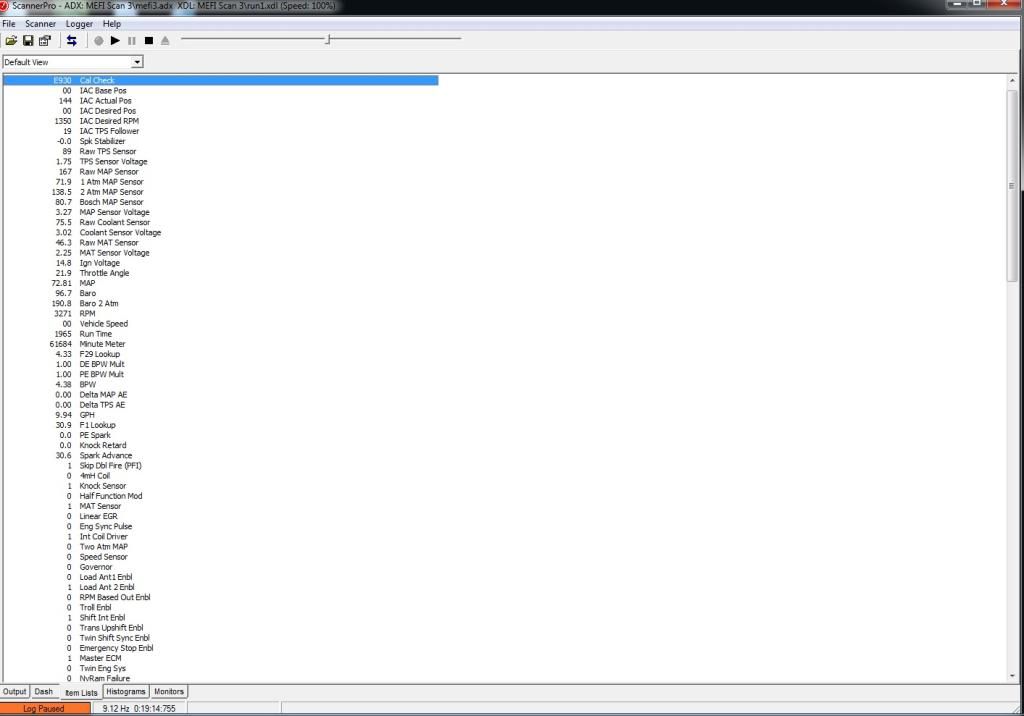

Alright conversion is complete from 2 barrel to 350 MAG MPI is complete. I have three hours of run time on my setup - trying to break it in. I am using a scan tool (USB) and scanner pro.

Questions:

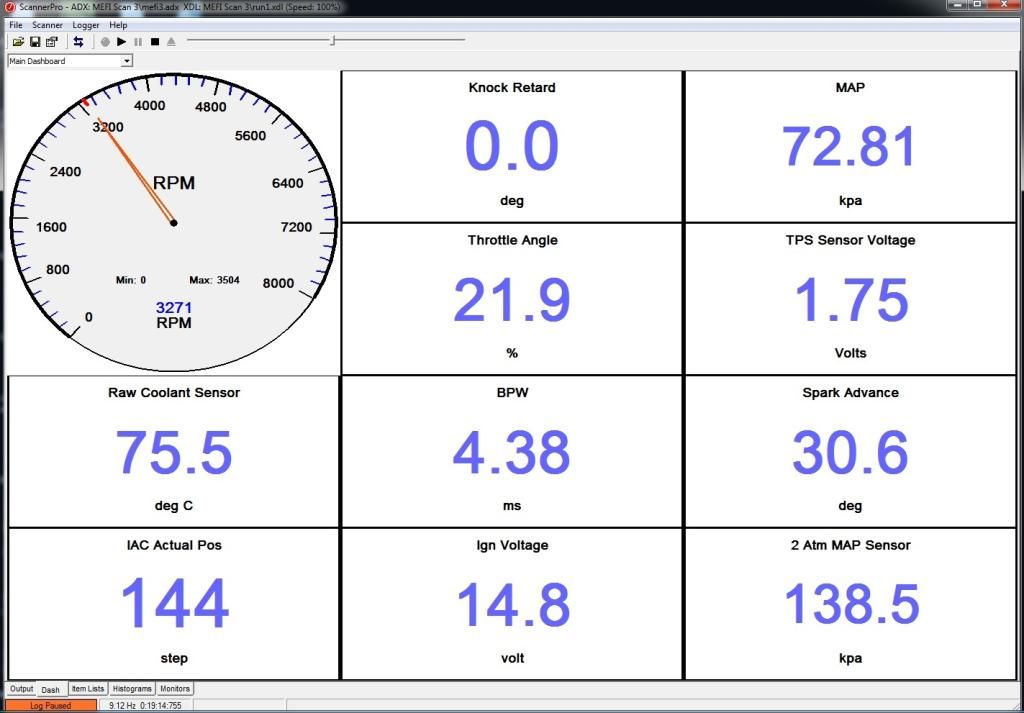

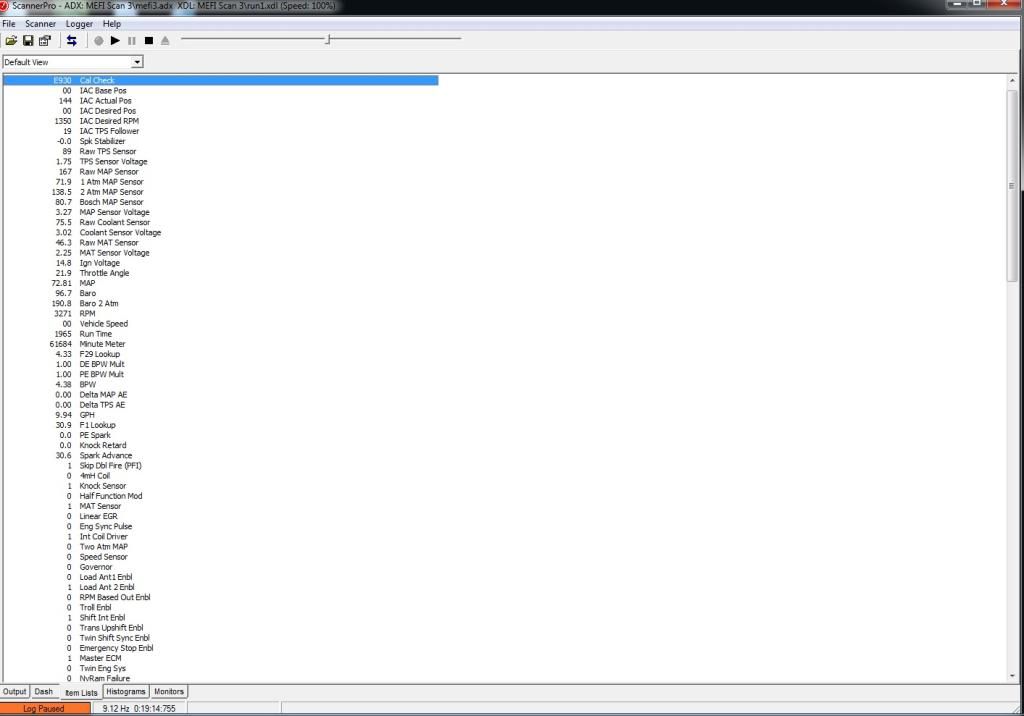

Under full load at 3000'ish RPMs the ECU is commanding 30deg spark advance, is this normal? I could not find the timing curve chart - maybe I overlooked it, I'm using manual #24.

I still need to put my timing light on it while operating it to see my actual max spark advance. I'll get that next run. I have a MEFI 3 ECU installed. I'm also running hyper pistons which actually recommend to decrease timing by - 2 degrees - if I understand correctly that means set base timing @ 6 deg instead of 8 deg.

My throttle body for the 1999-2000 MPI is the old school style - it has the stud in the center not the three studs on the outside diameter holding the flame arrestor. I have another old school throttle body, same style, that is in better shape (fresh water used - my installed was obliviously salt water). I would like to use the fresh water throttle body because of aesthetics but the stud is broken in the center. I've seen what appeared to me, to be a way to install with a clamp, not using a center stud. Can someone point me to where I can find the information or parts for using a clamp, if it's possible?

Another question: I have a 4 inch heat exchanger installed. The style installed has the raw water discharges coming from the left and right end caps to my manifolds. My port side manifold runs quite a bit warmer then my SB. I can keep my hand on it for over a min, so I don't believe it's detrimental. However, my ECU is installed on port side and heat kills electronics. In my system I do not have any type of diverter balls, my issue is flow diversion. Is there a way to use a diverter style in my setup or do I need to buy a new style heat exchanger to do what I'm wanting?

INFO/ISSUES FOR CONVERSION:

For anyone doing this conversion, you can not use the carbureted shift interrupt switch as designed in a MEFI system.

The carbureted style switch is normally open, which is what I had, it grounds out the negative coil wire to stumble the system. The MEFI system uses an normally closed switch that sends signal to the ECU to case stumble.

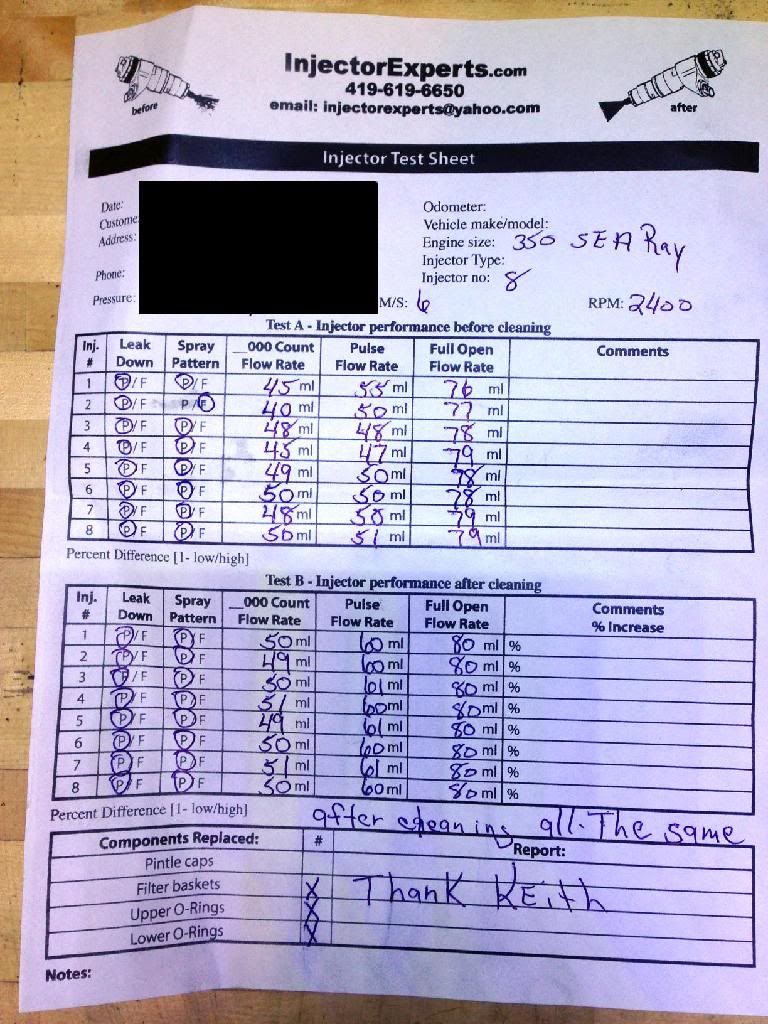

My fuel pressure under load is 32psi (cant remember exactly 32-34psi), right on for the older style MPI system. Newer style requires 43 psi, this was a correction to my first few posts about fuel pressure. For those that do not know there are two style regulators one is 32-34?psi the other is 43 psi.

I also had a problem on my first run with very high fuel pressure was around 60 psi, turned out to be the little filter between the pressure regulator and the cool fuel (old style) body. You'll see it after removal - the blockage causes a return side pressure increase which increases the overall pressure. I removed mine completely - I did not feel that I need it because I still have my Fuel Filter/Water Separator installed and that is where the return fuel goes back to.

Everything runs great, under load - but I get what feels like a small stumble around 1500-2000 rpm, I am thinking I have my plugs gapped incorrectly. I gapped at 45, I think they should have been 65 or so, I cant remember my plugs part number at the moment. Ill update when I have time to find it.

Ill be glad when I can get to WOT, right now I'm babying her.

Also side note it took me a year to complete this project and the first run I put her into the rocks in the river and destroyed the prop and done some damage to the transom area gel coat - I replaced the prop (no damage to the shaft) and did the gel coat repair to the transom. Basically life sucked for the first day - Karma I guess! Don't know who I pissed off!

She's back to normal now!

Thanks for reading.