DaffyJeffy

Seaman

- Joined

- May 28, 2015

- Messages

- 57

Hi everyone. I really need some help here...

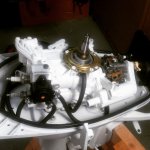

I did a complete restoration on my wife's grandfather's 1959 Johnson CD-16 5.5 hp. It was a labor of love so to speak, It had sat for a while and had poor compression when I got it so I decided to do a complete tear-down and rebuild. This project turned into a bit of a money-pit because I've had to buy so many parts. I also have a ridiculous amount of time invested in it at this point.

The 2-line tank was junk so I decided to replace it with a fuel pump as I've seen/read so many people do. Yesterday was my first day in the test tank and it didn't go well let's just say. Basically I could get it running...very poorly. It wouldn't come up to speed...then it would surge and die. I could keep it alive a bit by pumping the primer bulb but it ran like complete crap. It seemed way rich as the test tank was soon filled with an oily, carbony mess and my nice, freshly-painted new motor was all covered in soot. Yuck. It's like it was getting too rich a mixture and then air (when it surged) and then it would stall.

I used the conversion method where you jam a vacuum cap in one of the holes (removing the check valve) and use the port on that manifold for the "pulse". I've read on here that the pulse line has to be really short. Mine might be too long?

Or maybe I just have my lines plumbed wrong. Here's how I have it set up: Gas in from tank to glass filter bowl, out of filter bowl to the intake of the fuel pump, then out of the fuel pump to the carburetor. Again, the pulse is from the manifold covering the reed plate. Are my lines just too long?

Thanks in advance to anyone who can help me. I'm lost because I've literally rebuilt everything on this motor and therefore it could be anything...although I was very careful and this isn't my first rodeo (I've rebuilt more carburetors than I can count).

Also, if anybody is interested, here is what I've done to it: Carburetor rebuild with new float. Honed cylinders (after making sure everything met tolerance), new rings, new rods, all new gaskets, new thermostat, all new lower unit seals, impeller...she got the works...and new paint.

I did a complete restoration on my wife's grandfather's 1959 Johnson CD-16 5.5 hp. It was a labor of love so to speak, It had sat for a while and had poor compression when I got it so I decided to do a complete tear-down and rebuild. This project turned into a bit of a money-pit because I've had to buy so many parts. I also have a ridiculous amount of time invested in it at this point.

The 2-line tank was junk so I decided to replace it with a fuel pump as I've seen/read so many people do. Yesterday was my first day in the test tank and it didn't go well let's just say. Basically I could get it running...very poorly. It wouldn't come up to speed...then it would surge and die. I could keep it alive a bit by pumping the primer bulb but it ran like complete crap. It seemed way rich as the test tank was soon filled with an oily, carbony mess and my nice, freshly-painted new motor was all covered in soot. Yuck. It's like it was getting too rich a mixture and then air (when it surged) and then it would stall.

I used the conversion method where you jam a vacuum cap in one of the holes (removing the check valve) and use the port on that manifold for the "pulse". I've read on here that the pulse line has to be really short. Mine might be too long?

Or maybe I just have my lines plumbed wrong. Here's how I have it set up: Gas in from tank to glass filter bowl, out of filter bowl to the intake of the fuel pump, then out of the fuel pump to the carburetor. Again, the pulse is from the manifold covering the reed plate. Are my lines just too long?

Thanks in advance to anyone who can help me. I'm lost because I've literally rebuilt everything on this motor and therefore it could be anything...although I was very careful and this isn't my first rodeo (I've rebuilt more carburetors than I can count).

Also, if anybody is interested, here is what I've done to it: Carburetor rebuild with new float. Honed cylinders (after making sure everything met tolerance), new rings, new rods, all new gaskets, new thermostat, all new lower unit seals, impeller...she got the works...and new paint.

Last edited: