Hi,

I've been lurking about here for a few years now. I've been a sailor for 25 years, but, some years ago, I started thinking a classic fiberglass runabout was in my future. Well, the future's now as I just picked up a 1960 MFG Oxford. Really it's an Oxford hull as everything else is gone. It's been sitting in the back of a local yard for years & I brought it home yesterday.

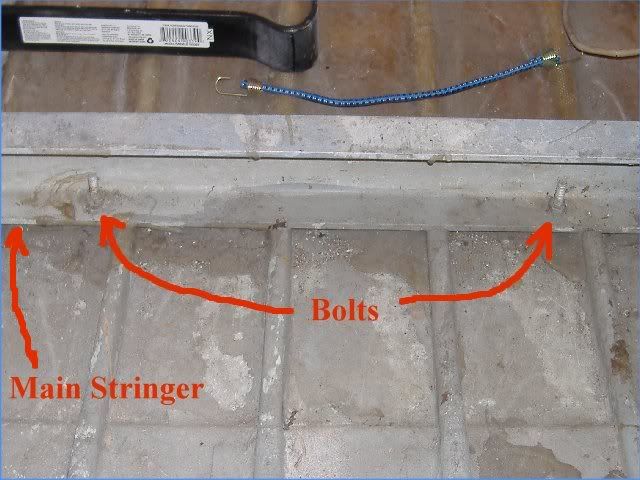

Here's where I need some help from the MFG owners in the forum. For some reason, one of the previous owners removed the aluminum C channel "stringers." I'd really appreciate it if somebody would take some measurements on theirs for me so that I can put them back in. Thanks up front.

I've been lurking about here for a few years now. I've been a sailor for 25 years, but, some years ago, I started thinking a classic fiberglass runabout was in my future. Well, the future's now as I just picked up a 1960 MFG Oxford. Really it's an Oxford hull as everything else is gone. It's been sitting in the back of a local yard for years & I brought it home yesterday.

Here's where I need some help from the MFG owners in the forum. For some reason, one of the previous owners removed the aluminum C channel "stringers." I'd really appreciate it if somebody would take some measurements on theirs for me so that I can put them back in. Thanks up front.