CRAPPIE_SLAYER

Cadet

- Joined

- Apr 16, 2010

- Messages

- 13

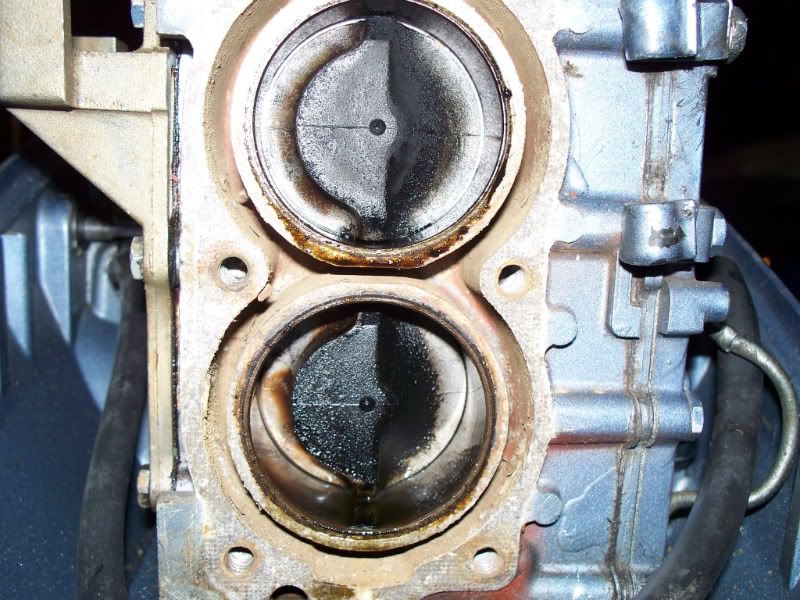

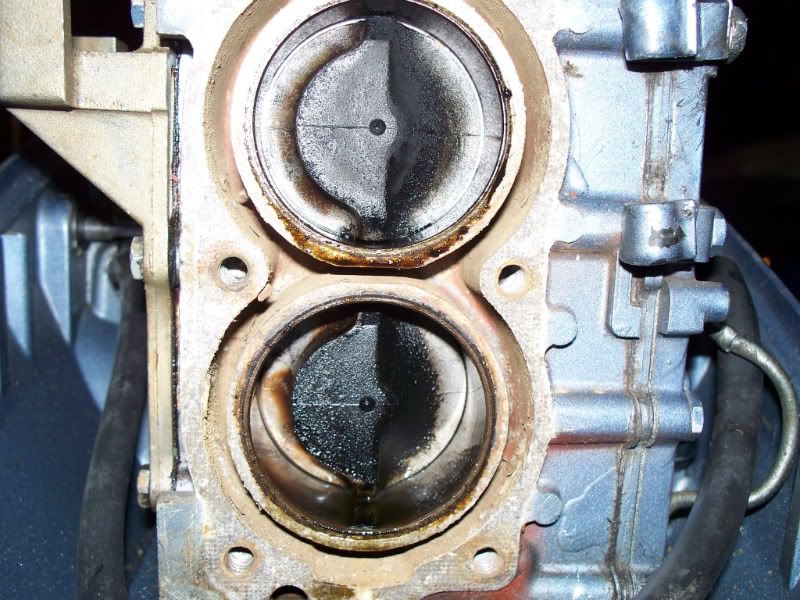

Hey guys! Just joined the site on a referal and I was hoping all of you evinrude gurus can help me out. Bought my motor last year and after having it out a half dozen times it started to miss BADLY the last time I was comming into the docks. I'm a 2-stroke novice, but got to looking at it and it looks to me like on of the coils is the original and the other has been replaced. Thought this may be the problem, but after getting some advice I decided to pull the head last night and this is what I found.

The lower cylinder seemed to have alot of buildup in it, so I took a closer look and found that there is actually a score mark that looks to run the length of the cylinder wall. You can see a brown streak on the wall that is actually the score.

By feel this mark is probably .001" - .003" deep. Checked the compression before I tore it down and it was 85#'s in the lower cylinder and 90#'s in the top, which was acceptable for this motor form everything that I have read about it. My question for you fellas is whether or not I can hone this out and re-ring it, or if I will need to bore the cylinders ad put oversized rings in it, or if it is even a problem? I am a machinist, so whatever the case is It shouldn't be a problem, just wondering what direction to head in. I took the head to work with me today to check it out and found that it was slightly warped. Lapped it off and it is now flat again. Want to get this baby running again, so can't wait to get your replies.

The lower cylinder seemed to have alot of buildup in it, so I took a closer look and found that there is actually a score mark that looks to run the length of the cylinder wall. You can see a brown streak on the wall that is actually the score.

By feel this mark is probably .001" - .003" deep. Checked the compression before I tore it down and it was 85#'s in the lower cylinder and 90#'s in the top, which was acceptable for this motor form everything that I have read about it. My question for you fellas is whether or not I can hone this out and re-ring it, or if I will need to bore the cylinders ad put oversized rings in it, or if it is even a problem? I am a machinist, so whatever the case is It shouldn't be a problem, just wondering what direction to head in. I took the head to work with me today to check it out and found that it was slightly warped. Lapped it off and it is now flat again. Want to get this baby running again, so can't wait to get your replies.