Here is my tentative order from USC. As background it's an 18' boat, going to be glassing the transom, ski ladder, stringers, bulkheads and deck. Will be gelcoating the inner transom area, bilge below engine, deck from the front of the bench seat back and ski locker in grey. Will also be gelcoating two holes in the hull.

If anyone sees anything missing or a quantity out of whack please fee free to comment. I plan to buy rollers and other nic-nacks locally. When I finish I hope to come back with an update on how this worked out so others with similar size boats have an idea of what they might need.

Quanity Product Description and/or Catalog Number

50yds 1-1/2oz CSM

30yds 1708 Biaxial

4 5gal 435 Resin

2 4gal ¼" Cabosil (1.71lb)

1 4lb tub ¼" Chopped Strand

1 2lb Density Foam 80lb kit

1 Measur-matic

1 10 oz tube 3m 5200

1 Box of 24 2" Chip Brushes

1 Fiberglass Roller ½"x4"

1 Mixing Cups Quart Sleeve/50

1 Mixing Cups 2.5qt Sleeve/25

1 Graduated Cups 8oz Sleeve/25

1 Tongue Depressors Pack of 50

1 Stir Sticks Pack of 50

1 1pt Surfacing Wax

1 1gal White Gelcoat

1 4oz Black Tint

1 1oz Halyard Tint

1 1oz Grey Tint

1 1oz Yellow Tint

1 1oz Brown Colonial Tint

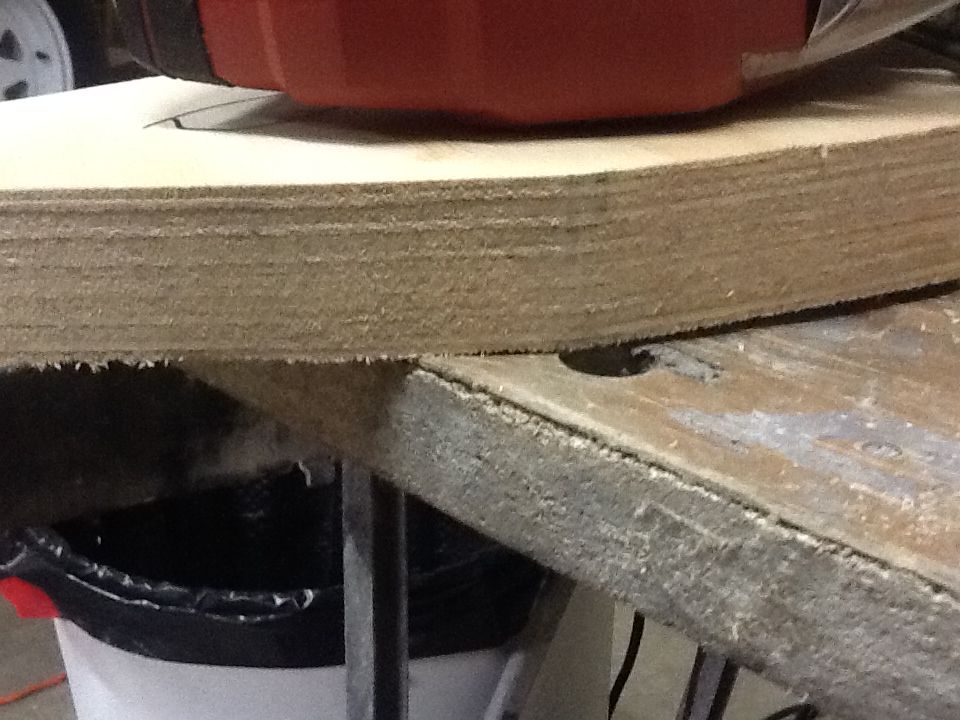

And the sanded face

And the sanded face