Rranger

Chief Petty Officer

- Joined

- May 18, 2009

- Messages

- 465

Re: !976 22' Fiberform

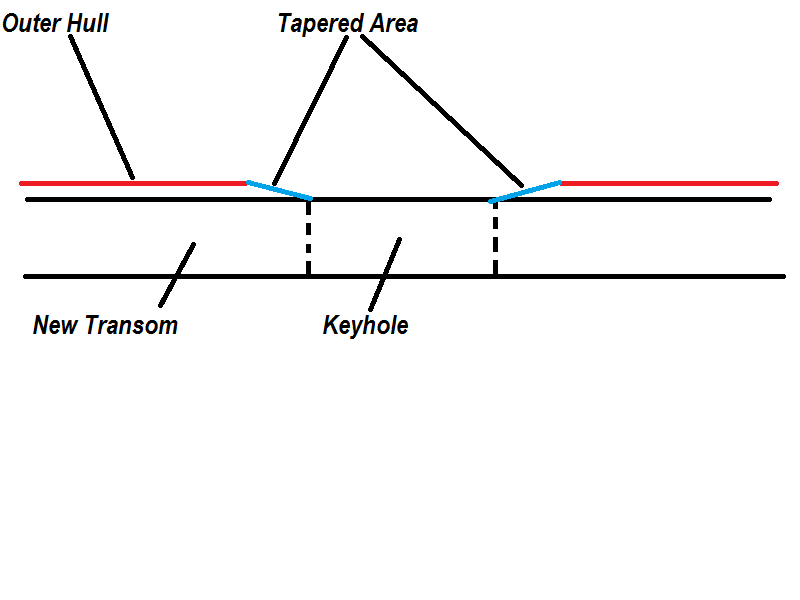

A little help from the pro's please. My project is coming along, doing the tedious corner and bottom cleaning of the old transom. A little bit more sanding of the transom and then good to go. The old transom hole is to big for the mercury 350 with the mercury 188 outdrive so I have to do a total wood transom and then patch the fiberglass hole on the back of the transom and then cut to fit my engine unit.

A little help from the pro's please. My project is coming along, doing the tedious corner and bottom cleaning of the old transom. A little bit more sanding of the transom and then good to go. The old transom hole is to big for the mercury 350 with the mercury 188 outdrive so I have to do a total wood transom and then patch the fiberglass hole on the back of the transom and then cut to fit my engine unit.

The question I have is should I fill the fiberglass hole first, using a temp backing board on the inside with some wax paper in between?

Or do I put my new transom temporarily in place trace the present hole, then remove and epoxy around the trace, and epoxy the inside of the transom and then reinsert and clamp, and wipe up the epoxy leaking all around the hole.

Or is there a better way lol?

A little help from the pro's please. My project is coming along, doing the tedious corner and bottom cleaning of the old transom. A little bit more sanding of the transom and then good to go. The old transom hole is to big for the mercury 350 with the mercury 188 outdrive so I have to do a total wood transom and then patch the fiberglass hole on the back of the transom and then cut to fit my engine unit.

A little help from the pro's please. My project is coming along, doing the tedious corner and bottom cleaning of the old transom. A little bit more sanding of the transom and then good to go. The old transom hole is to big for the mercury 350 with the mercury 188 outdrive so I have to do a total wood transom and then patch the fiberglass hole on the back of the transom and then cut to fit my engine unit.The question I have is should I fill the fiberglass hole first, using a temp backing board on the inside with some wax paper in between?

Or do I put my new transom temporarily in place trace the present hole, then remove and epoxy around the trace, and epoxy the inside of the transom and then reinsert and clamp, and wipe up the epoxy leaking all around the hole.

Or is there a better way lol?