Rick Stephens

Admiral

- Joined

- Aug 13, 2013

- Messages

- 6,118

Alpha 1 - Replaced bellows, gaskets, still water in drive bellows and shift compartment

I am kind of losing my mind on this.

Short version: found water in bellows during last winterization, replaced the bellows, gimbal bearing, ujoint crosses, seals, and while there, the water pump and sundry other maintenance items - come spring still finding water in the bellows and shift linkage compartment.

Long version. Bought 1990 Mercruiser 3 liter boat last year. Been going through rebuilding and replacing whatever to make it as 100% as I can. Expected stuff like poor bellows. No fuss. I read everything and pull up ChrisâÂÂs videos when I need a hint. I have owned several different shops and worked on everything from tugboats to cranes to pickups and computers. Mercruisers are fairly straightforward if a bit âÂÂspecial toolâ needy.

First thing of note, the bell housing and transom are original and have never been in salt water - very pristine. The leg looks like it was bought as a rebuilt replacement and had been in some salt water before rebuild, has some pitting on the cavitation plate and the mating surface to the bell housing is a bit rough. It is smooth operating, quiet, and the pressure tests are all perfection. So I was good with that.

I replaced all the bellows with original Merc parts. Water pump, crosses, new sealed gimbal completed the job along with oil and a mag tip plug for the bottom gearcase. Winterized and parked it. Took it out in the spring for one day, when back in, pulled the leg and it looked dry. All was good.

Next time using it the boat started dying when shifted. Know what that is, pulled the leg to check the shift cable - bad news - water and grease mix in the bellows and shift linkage area again. So cleaned everything and resealed it, replaced the gasket and paid special attention to everything. Took it out, same thing, water. Did that a number of times, every time after a cleanup of the shift cable and a new gasket kit for the leg, after a day or two it starts having shift problems, pull the leg and thereâÂÂs water.

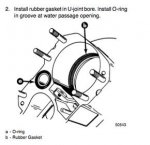

So last week stuck another new OEM bellows in it. Went through everything I could - inspected all the components at each end where the bellows attaches - the transom gimbal mount and bell housing and leg. Nothing. I would swear on my mothers grave, if she were dead and had one, that the bellows install is perfect. It went on sweet. All new clamps, water passage oring, gasket and square rubber seal. DidnâÂÂt replace the exhaust bellows since it plays no part. Take it to the lake, runs absolutely perfect for one day, next day shift death. Pull it part in the campground - water.

This time I silicon the water passage o-ring in, since the face of the leg is rough there, maybe I'm pumping water in. New gasket, run for a day, starts shifting bad - water.

Next, silicon the entire o-ring and gasket faces between leg and bell housing. No difference. Runs perfect till it wonâÂÂt shift without dying.

I gotta ask for help. Is it possible there is a crack in the upper gear case letting water in? What am I missing? It is just not that complicated putting a bellows on.

Thanks for thoughts.

Rick

I am kind of losing my mind on this.

Short version: found water in bellows during last winterization, replaced the bellows, gimbal bearing, ujoint crosses, seals, and while there, the water pump and sundry other maintenance items - come spring still finding water in the bellows and shift linkage compartment.

Long version. Bought 1990 Mercruiser 3 liter boat last year. Been going through rebuilding and replacing whatever to make it as 100% as I can. Expected stuff like poor bellows. No fuss. I read everything and pull up ChrisâÂÂs videos when I need a hint. I have owned several different shops and worked on everything from tugboats to cranes to pickups and computers. Mercruisers are fairly straightforward if a bit âÂÂspecial toolâ needy.

First thing of note, the bell housing and transom are original and have never been in salt water - very pristine. The leg looks like it was bought as a rebuilt replacement and had been in some salt water before rebuild, has some pitting on the cavitation plate and the mating surface to the bell housing is a bit rough. It is smooth operating, quiet, and the pressure tests are all perfection. So I was good with that.

I replaced all the bellows with original Merc parts. Water pump, crosses, new sealed gimbal completed the job along with oil and a mag tip plug for the bottom gearcase. Winterized and parked it. Took it out in the spring for one day, when back in, pulled the leg and it looked dry. All was good.

Next time using it the boat started dying when shifted. Know what that is, pulled the leg to check the shift cable - bad news - water and grease mix in the bellows and shift linkage area again. So cleaned everything and resealed it, replaced the gasket and paid special attention to everything. Took it out, same thing, water. Did that a number of times, every time after a cleanup of the shift cable and a new gasket kit for the leg, after a day or two it starts having shift problems, pull the leg and thereâÂÂs water.

So last week stuck another new OEM bellows in it. Went through everything I could - inspected all the components at each end where the bellows attaches - the transom gimbal mount and bell housing and leg. Nothing. I would swear on my mothers grave, if she were dead and had one, that the bellows install is perfect. It went on sweet. All new clamps, water passage oring, gasket and square rubber seal. DidnâÂÂt replace the exhaust bellows since it plays no part. Take it to the lake, runs absolutely perfect for one day, next day shift death. Pull it part in the campground - water.

This time I silicon the water passage o-ring in, since the face of the leg is rough there, maybe I'm pumping water in. New gasket, run for a day, starts shifting bad - water.

Next, silicon the entire o-ring and gasket faces between leg and bell housing. No difference. Runs perfect till it wonâÂÂt shift without dying.

I gotta ask for help. Is it possible there is a crack in the upper gear case letting water in? What am I missing? It is just not that complicated putting a bellows on.

Thanks for thoughts.

Rick

Last edited: