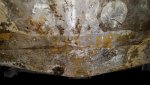

I have an '82 16' Sylvan Sportster that I just picked up and got into. It needed floors and Transom and now a Transom skin. It looks like the milky way (I'll try posting pics).

I'm looking for any advice on the best way to repair. This is the only area on the boat I have found corrosion and holes. I'd hate to have to scrap it but I'm only into it for $400 and it came with a good running Johnson 75 and a nice Sealion bunk...and paperwork.

That said, I'll can the project if need be, however I'd like to know if this repair is worth it. Any advice would be much appreciated. Thank you for your time.

I'm looking for any advice on the best way to repair. This is the only area on the boat I have found corrosion and holes. I'd hate to have to scrap it but I'm only into it for $400 and it came with a good running Johnson 75 and a nice Sealion bunk...and paperwork.

That said, I'll can the project if need be, however I'd like to know if this repair is worth it. Any advice would be much appreciated. Thank you for your time.

Attachments

Last edited: