Get_afterit

Cadet

- Joined

- May 22, 2021

- Messages

- 20

Hi Guys,

long time lurker here, have finally decided to take the plunge and restore a fibreglass boat.

As the title states, it is a 1979 Cobia Sportster 18vbr - hull and top cap appear to be in good shape for the year, the typical wear and tear that you would expect with a 40+ year old boat but appears to be in good shape cosmetically. (this is my first fibreglass boat however so my experience is limited with them)

I plan to document the restoration and post photos and probably ask a lot of questions along the way.

however the transom, stringers, and floor need to be replaced.

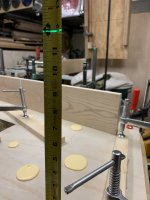

I've taken the first step and have taken the boat off the trailer, and blocked up.

I used the stringers as they are still pretty much in tact to level it from port to starboard at the rear of the boat.

question #1 -

Do I also need to have it level from bow to stern as well? if so should I use the stringers as the reference? If I do level it bow to stern do I need to be concerned with water accumulating in the bottom of the boat since I am going to pretty much gut the whole thing

I have 2 blocks supporting the transom and an 8' length running down the keel, is this sufficient for now? I plan to run a full length support on the outer chines and use those to level the front of boat before I start cutting out the stringers.

I think I have settled on removing the cap to gain access to the stringers and transom, I plan the dimension the interior beam to make sure it does not splay outwards once I remove the cap.

After I support my outer chines and write down dimensions would removing the cap be the next step?

I have attached some photos of my blocking setup - just want to make sure its strong enough and some other photos of the boat as well.

Also does anyone have any experience with these boats? how they ride in rough waters? are they considered well built? is it even worth saving?

Thanks for the replys!

long time lurker here, have finally decided to take the plunge and restore a fibreglass boat.

As the title states, it is a 1979 Cobia Sportster 18vbr - hull and top cap appear to be in good shape for the year, the typical wear and tear that you would expect with a 40+ year old boat but appears to be in good shape cosmetically. (this is my first fibreglass boat however so my experience is limited with them)

I plan to document the restoration and post photos and probably ask a lot of questions along the way.

however the transom, stringers, and floor need to be replaced.

I've taken the first step and have taken the boat off the trailer, and blocked up.

I used the stringers as they are still pretty much in tact to level it from port to starboard at the rear of the boat.

question #1 -

Do I also need to have it level from bow to stern as well? if so should I use the stringers as the reference? If I do level it bow to stern do I need to be concerned with water accumulating in the bottom of the boat since I am going to pretty much gut the whole thing

I have 2 blocks supporting the transom and an 8' length running down the keel, is this sufficient for now? I plan to run a full length support on the outer chines and use those to level the front of boat before I start cutting out the stringers.

I think I have settled on removing the cap to gain access to the stringers and transom, I plan the dimension the interior beam to make sure it does not splay outwards once I remove the cap.

After I support my outer chines and write down dimensions would removing the cap be the next step?

I have attached some photos of my blocking setup - just want to make sure its strong enough and some other photos of the boat as well.

Also does anyone have any experience with these boats? how they ride in rough waters? are they considered well built? is it even worth saving?

Thanks for the replys!