waterboy222

Seaman

- Joined

- Dec 5, 2011

- Messages

- 56

Re: covering up the woven material in a few spots.

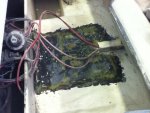

I could take some pics, but all you'd see is everything inside painted white. Even the bulkheads and sponsons have been painted inside, its weird. I can see quite a few repair jobs too, its taken a beating in its day. I think he said its vinylester?? Does that sound right? I'd have to check the email again.

The conversation was so rushed, i cant remember it all.. Its whatever product IS NOT affected by ethanol, because he said my fuel tanks don't need to be redone..

I could take some pics, but all you'd see is everything inside painted white. Even the bulkheads and sponsons have been painted inside, its weird. I can see quite a few repair jobs too, its taken a beating in its day. I think he said its vinylester?? Does that sound right? I'd have to check the email again.

The conversation was so rushed, i cant remember it all.. Its whatever product IS NOT affected by ethanol, because he said my fuel tanks don't need to be redone..