yep...it's impossible to overtighten just using hand strength. Where a mistake can be made is after hand snugging the castle nut, some see that the cotter pin hole is just slightly ahead of the "slot"...so they take a tool and use it to snug to the hole. That might make it too tight. I always go loose.

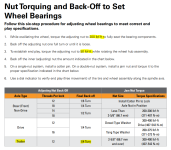

and I see timken says 50lb/ft.....so use that if you want,...no debate.

and I see timken says 50lb/ft.....so use that if you want,...no debate.