Alright, so last week I was able to do another water test after putting the carb back on. The new jets didn't make any noticeable difference, the knocking sound still remains under engine load. So I was a bit disappointed to say the least, but athe least I know it's not a carburetion issue.

Then I did some digging on the forums and came across someone else who had the same exact symptoms going on, so I posted the link to the thread below. Now I'm curious if my problem is indeed a head gasket (or similar), which is what fixed the problem for the OP in the other thread.

I also conducted both a compression test and a leak down test.

Leak down test results:

Cyl 1.* 11%

Cyl 2.* 28%

Cyl 3.* 17%

Cyl 4. 9%

Cyl 5. 9%

Cyl 6. 9%

Compression test results:

Cyl 1.* 140psi

Cyl 2.* 120psi

Cyl 3.* 152psi

Cyl 4. 160psi

Cyl 5. 157psi

Cyl 6. 157psi

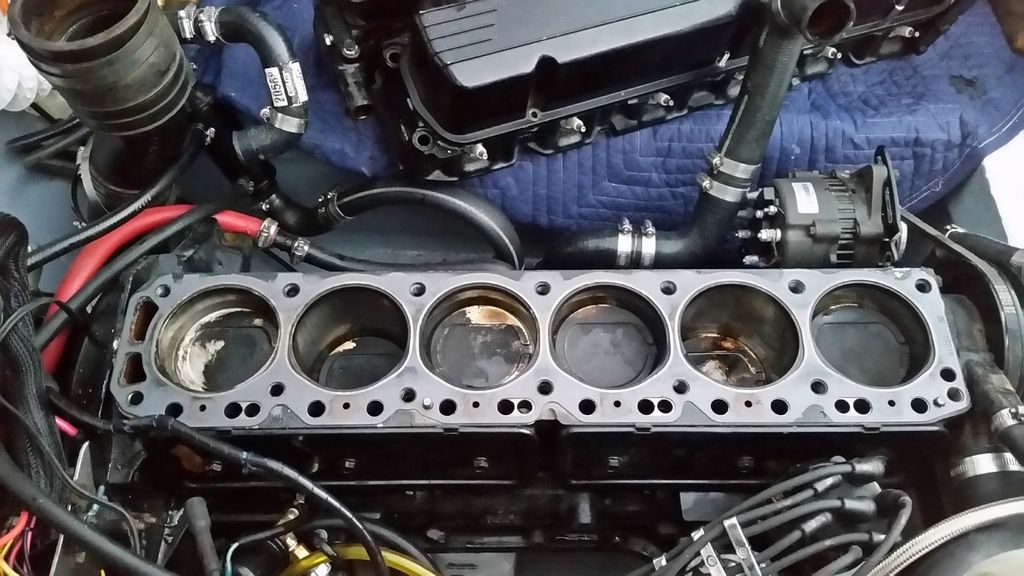

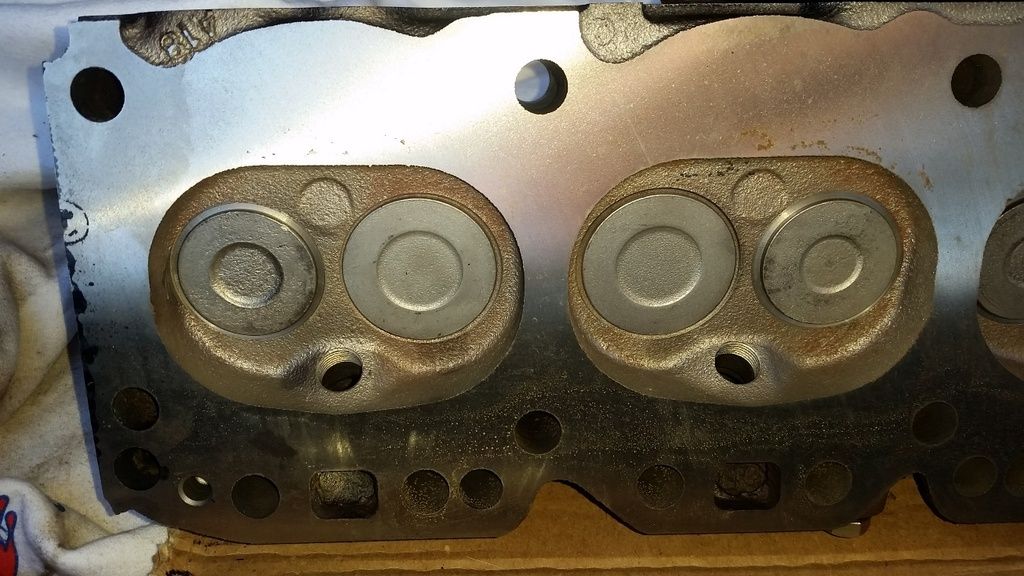

I think my best course of action is to remove and inspect the cylinder head. I'll be looking closely at cylinders 1-3.