seedlings

Petty Officer 3rd Class

- Joined

- Jun 5, 2009

- Messages

- 92

1979 AMF Crestliner Muskie 550 14'

1978 Evinrude 70hp

13.25 x 17 pitch prop

30mph, 4500rpm WOT with normal load of 2 adults, 2 kids.

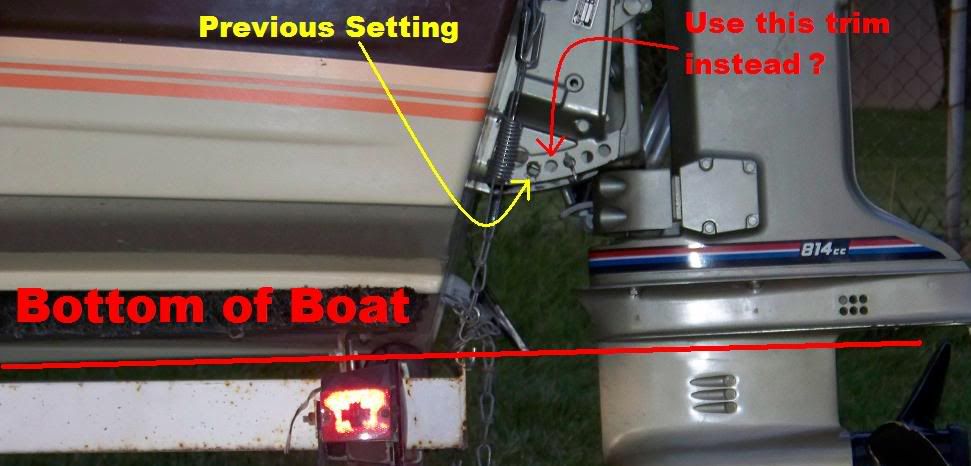

Just getting this boat going after a couple of decades in storage, and now am trying to improve performance. After reading here about adjusting Manual trim by how the AV plate looks in comparison to the bottom of the boat, here's how it looks now. I raised the motor about an inch and a quarter (two holes), and the trim out two holes. We had trouble getting on plane, it takes about 45 seconds, plus couldn't get over 15mph (trying to get a tube out of the water).

This has raised the top of the motor mount above the boat. Is this OK?

And finally, the back fin of the lower unit had been bent, chipped and broken. I tried to tap what was left back in place, but lost another 1/4 inch of metal under the prop. Tell me how bad is this?

Thanks all,

CHAD

1978 Evinrude 70hp

13.25 x 17 pitch prop

30mph, 4500rpm WOT with normal load of 2 adults, 2 kids.

Just getting this boat going after a couple of decades in storage, and now am trying to improve performance. After reading here about adjusting Manual trim by how the AV plate looks in comparison to the bottom of the boat, here's how it looks now. I raised the motor about an inch and a quarter (two holes), and the trim out two holes. We had trouble getting on plane, it takes about 45 seconds, plus couldn't get over 15mph (trying to get a tube out of the water).

This has raised the top of the motor mount above the boat. Is this OK?

And finally, the back fin of the lower unit had been bent, chipped and broken. I tried to tap what was left back in place, but lost another 1/4 inch of metal under the prop. Tell me how bad is this?

Thanks all,

CHAD