Redeyedwiggler

Seaman

- Joined

- Aug 19, 2004

- Messages

- 56

I found this product..

http://durafix.com/index.html

I placed an order today and wanted to share my repair project so that others can form an opinion about this product with me..

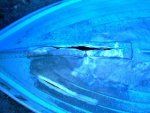

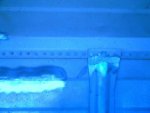

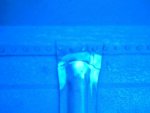

I'm no pro and this will be my first attempt at fixing an extremely damaged aluminum boat.

***edit***

Durafix was a bust on this project.. I find that the product works well on level surfaces only.

this thread is dead from here on out.

see last post for my finished boat project!

http://durafix.com/index.html

I placed an order today and wanted to share my repair project so that others can form an opinion about this product with me..

I'm no pro and this will be my first attempt at fixing an extremely damaged aluminum boat.

***edit***

Durafix was a bust on this project.. I find that the product works well on level surfaces only.

this thread is dead from here on out.

see last post for my finished boat project!