stevepamboukes

Seaman

- Joined

- Jul 22, 2016

- Messages

- 52

Hello again!

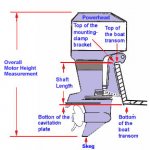

Continuing to investigate what feels like "slippage" on my Evinrude 40HP Selectric shift outboard, I've dismantled the LU and am preparing to install a long shaft conversion kit, replace a bunch of bearings and seals. To review the symptoms:

-Engine sounds great and runs great. Propulsion feels roughly proportional to engine speed until about 1/2 throttle. After that, engine will continue to spool up, but no more forward thrust is made.

Things I've verified:

-I have 12VDC back to both the F and R coils

-Both coils test within resistance specification

-Propeller is not spun about its hub

-Passed the spin test (w/ engine off, put into forward, it spins infinitely in reverse direction but, spinning in forward direction, it will go half turn or so then lock up. This checks out for both forward and reverse)

Which leaves me with thinking either:

1. I need the longshaft conversion, to get that prop further in the water and reduce slosh/cavitation? (its getting the long shaft either way)

2. And/or the forward gear spring is slipping about the forward gear hub.

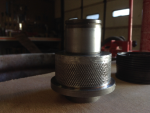

SO I wanted to get your eyes on option #2. Here are some photos of the forward spring and gear hub.

I see that the hub is mostly knurled. I do see light galling on the hub, but that's why I need a second set of eyes. Does that look like a normal, acceptable amount of wear, or is that an indicator that I'm slipping the spring? Being optimistic, I would imagine it would accumulate light wear from an instant of slippage, basically every time you engage forward. For that quick instant between neutral and forward, where the spring is still wrapping tight, you could have minor minor slip that would show wear like such? The galling doesn't look heavy enough to me to be a consequence of constant, continuous slippage.

But, i'm interested in your opinions. If that IS worn, what are your thoughts on swapping the front assembly with the rear? The manual does say they are the same... funny thing to me is the reverse assembly (not pictured) actually isn't knurled at all...

Thanks!

Continuing to investigate what feels like "slippage" on my Evinrude 40HP Selectric shift outboard, I've dismantled the LU and am preparing to install a long shaft conversion kit, replace a bunch of bearings and seals. To review the symptoms:

-Engine sounds great and runs great. Propulsion feels roughly proportional to engine speed until about 1/2 throttle. After that, engine will continue to spool up, but no more forward thrust is made.

Things I've verified:

-I have 12VDC back to both the F and R coils

-Both coils test within resistance specification

-Propeller is not spun about its hub

-Passed the spin test (w/ engine off, put into forward, it spins infinitely in reverse direction but, spinning in forward direction, it will go half turn or so then lock up. This checks out for both forward and reverse)

Which leaves me with thinking either:

1. I need the longshaft conversion, to get that prop further in the water and reduce slosh/cavitation? (its getting the long shaft either way)

2. And/or the forward gear spring is slipping about the forward gear hub.

SO I wanted to get your eyes on option #2. Here are some photos of the forward spring and gear hub.

I see that the hub is mostly knurled. I do see light galling on the hub, but that's why I need a second set of eyes. Does that look like a normal, acceptable amount of wear, or is that an indicator that I'm slipping the spring? Being optimistic, I would imagine it would accumulate light wear from an instant of slippage, basically every time you engage forward. For that quick instant between neutral and forward, where the spring is still wrapping tight, you could have minor minor slip that would show wear like such? The galling doesn't look heavy enough to me to be a consequence of constant, continuous slippage.

But, i'm interested in your opinions. If that IS worn, what are your thoughts on swapping the front assembly with the rear? The manual does say they are the same... funny thing to me is the reverse assembly (not pictured) actually isn't knurled at all...

Thanks!