Otte

Petty Officer 1st Class

- Joined

- Jul 26, 2011

- Messages

- 273

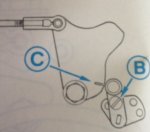

Please let me know if there is a more detailed explanation of how to re-do the carburetors for a 1989 50HP Evinrude. I have a Sealoc repair manual for my engine but it lacks the detail I need to remove the throttle links.

1. I have the carburetor kit with float from iboats.

2. I have removed the air silencer front and back off the carbs.

Now I have to get the nuts off the carbs in order to remove them from the engine block but the throttle links are in the way of removal. How do I do this? Thanks for any help you folks can give me. I hope this photobucket thing works.

<iframe src="http://s900.photobucket.com/user/Bret_Otte/story/40047/embed" width="650" height="400" frameborder="0" scrolling="no"></iframe>

1. I have the carburetor kit with float from iboats.

2. I have removed the air silencer front and back off the carbs.

Now I have to get the nuts off the carbs in order to remove them from the engine block but the throttle links are in the way of removal. How do I do this? Thanks for any help you folks can give me. I hope this photobucket thing works.

<iframe src="http://s900.photobucket.com/user/Bret_Otte/story/40047/embed" width="650" height="400" frameborder="0" scrolling="no"></iframe>