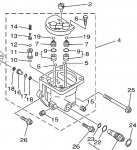

Fastrac PTT from 1993 J200TZATS 200 HP Johnson. The problem I am having is with the trim. It started after replacing the tilt ram seal and O rings and the filter and O ring between the valve body and pump motor. When the motor contacts the trim rams and I continue to hold the switch in the down position it trims down very slowly. I know that the trim operation is much slower than the tilt but it is now taking 2 to 3 minutes of constantly running the pump to get it from where it contacts the trim rams to fully trim down. It is as if the fluid in the lower section of the trim cylinders cannot escape freely and the force of the tilt cylinder pulling down on the engine is slowly pushing down on the trim rams forcing the oil out of the bottom of the trim cylinders through a valve that is not opening completely. Everything else, Trim up, Tilt up, Tilt down and Holding in any position seems to be working as expected. It is only Trimming down that is an issue.

Related information:

Initial problem Resolved which started the new trim problem – The unit was working fine but the seal on the tilt ram was leaking so I decided I would replace it. I purchased a seal and O ring kit for the unit and proceeded to make the repair. I removed the PTT from the boat, removed the tilt ram and replaced the seal as well as the O rings on the cap and piston. I was careful to ensure that the springs and check valve balls in the piston stayed in place when I removed and reinstalled the piston on to the ram shaft. Since I had the parts and it was simple to do I also replaced the filter and O ring between the valve body and electric pump motor. I never touched the trim rams or the bypass screw as it is frozen in the closed position. I put it back together filled it up with oil and installed it on the boat. It would raise the engine but would not hold in any position except for full up and when full up if I just engaged the down switch for a fraction of a second the PTT would lose its hold and slowly lower all the way down. I bled the air out and continued to top off until full but it still would not hold. I took it back off and noticed that I could extend and compress the tilt ram manually by hand and knew something did not go back together right. I was running out of time and decided to drop it off at a local shop. The mechanic got the tilt ram working properly. I suspect I had the O rings reversed between the cap and the piston which was allowing fluid to pass around the piston. One was a bit thicker and I think I put the thicker one on the cap when it should have gone on the piston. I am not sure if the shop just reversed them to fix that problem and the mechanic could not tell me what they had done to fix it.

Current problem needing a solution – The Mechanic said that in the vice on the bench the trim rams do not contract which he believes should. Based on some other posts on the subject I believe this is normal. He thought it may be a missing a check balls in one of the 4 check valves that are visible when you lift the motor off the valve body. He says there are what appears to be 4 valves and only 3 have balls in them and thinks one may have fallen out when I replaced the filter.

I took it back home, put it on the boat, bled and refilled it and all is working well except for the Trim rams as described at the top of this post. The trim rams extend properly but will not contract easily. The mechanic obviously got deeper into the valve body than I did to replace the filter and may have done something that is causing the trim problem. He said something in the valve body was in upside down but as I recall the only thing in the top of the VB that I touched was the filter so maybe he opened it up further and flipped something he should not have or lost the check ball .

.

Any knowledge or advise that will help me figure this out is greatly appreciated.

Related information:

Initial problem Resolved which started the new trim problem – The unit was working fine but the seal on the tilt ram was leaking so I decided I would replace it. I purchased a seal and O ring kit for the unit and proceeded to make the repair. I removed the PTT from the boat, removed the tilt ram and replaced the seal as well as the O rings on the cap and piston. I was careful to ensure that the springs and check valve balls in the piston stayed in place when I removed and reinstalled the piston on to the ram shaft. Since I had the parts and it was simple to do I also replaced the filter and O ring between the valve body and electric pump motor. I never touched the trim rams or the bypass screw as it is frozen in the closed position. I put it back together filled it up with oil and installed it on the boat. It would raise the engine but would not hold in any position except for full up and when full up if I just engaged the down switch for a fraction of a second the PTT would lose its hold and slowly lower all the way down. I bled the air out and continued to top off until full but it still would not hold. I took it back off and noticed that I could extend and compress the tilt ram manually by hand and knew something did not go back together right. I was running out of time and decided to drop it off at a local shop. The mechanic got the tilt ram working properly. I suspect I had the O rings reversed between the cap and the piston which was allowing fluid to pass around the piston. One was a bit thicker and I think I put the thicker one on the cap when it should have gone on the piston. I am not sure if the shop just reversed them to fix that problem and the mechanic could not tell me what they had done to fix it.

Current problem needing a solution – The Mechanic said that in the vice on the bench the trim rams do not contract which he believes should. Based on some other posts on the subject I believe this is normal. He thought it may be a missing a check balls in one of the 4 check valves that are visible when you lift the motor off the valve body. He says there are what appears to be 4 valves and only 3 have balls in them and thinks one may have fallen out when I replaced the filter.

I took it back home, put it on the boat, bled and refilled it and all is working well except for the Trim rams as described at the top of this post. The trim rams extend properly but will not contract easily. The mechanic obviously got deeper into the valve body than I did to replace the filter and may have done something that is causing the trim problem. He said something in the valve body was in upside down but as I recall the only thing in the top of the VB that I touched was the filter so maybe he opened it up further and flipped something he should not have or lost the check ball

Any knowledge or advise that will help me figure this out is greatly appreciated.

Last edited: