psykosteel

Seaman Apprentice

- Joined

- May 7, 2013

- Messages

- 40

Hello iboaters,

I've been reading up on a lot of great resto threads and appreciate all of the information that has been shared. It's a bit overwhelming at first to come in and try to soak it all up, but I'm working on it.

Anyhow so I purchased my first boat and it seemed like a good enough deal, 85 Four Winns 170 Candia deck boat. My wife wanted a pontoon and I wanted a ski boat, so this was an in-between that seemed to fit the bill. The interior needed work and the paint was faded and heavily oxidized, but no cracks in the hull and the motor is strong so I purchased it well knowing that all had to be done and probably more, boy was I right.

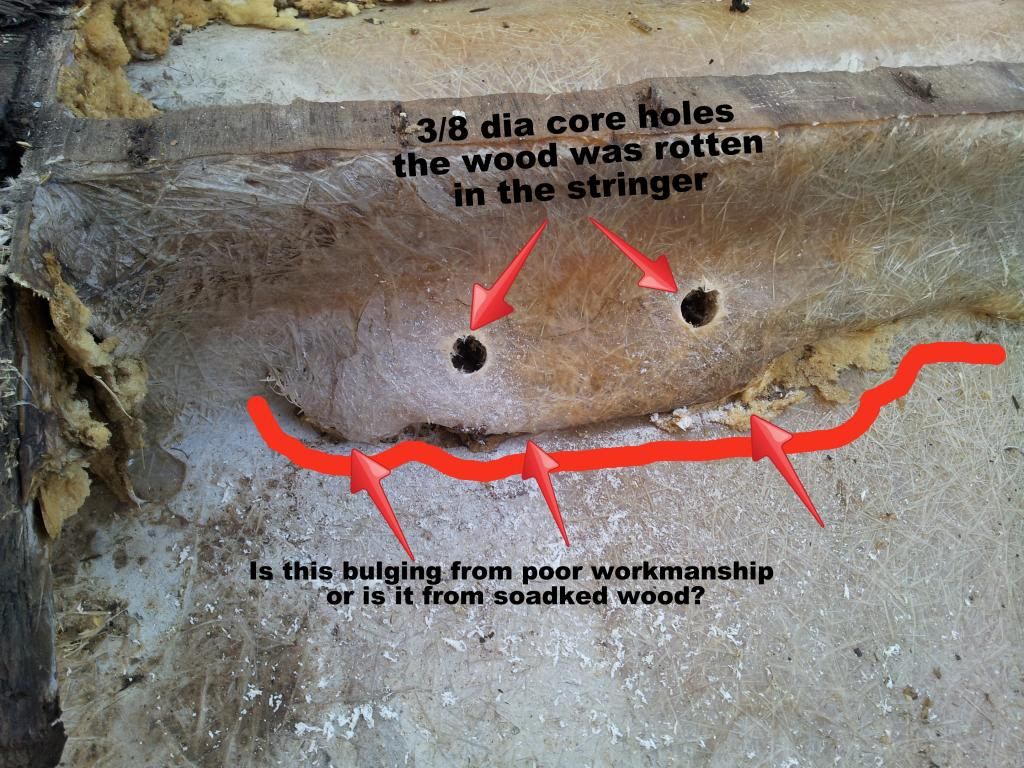

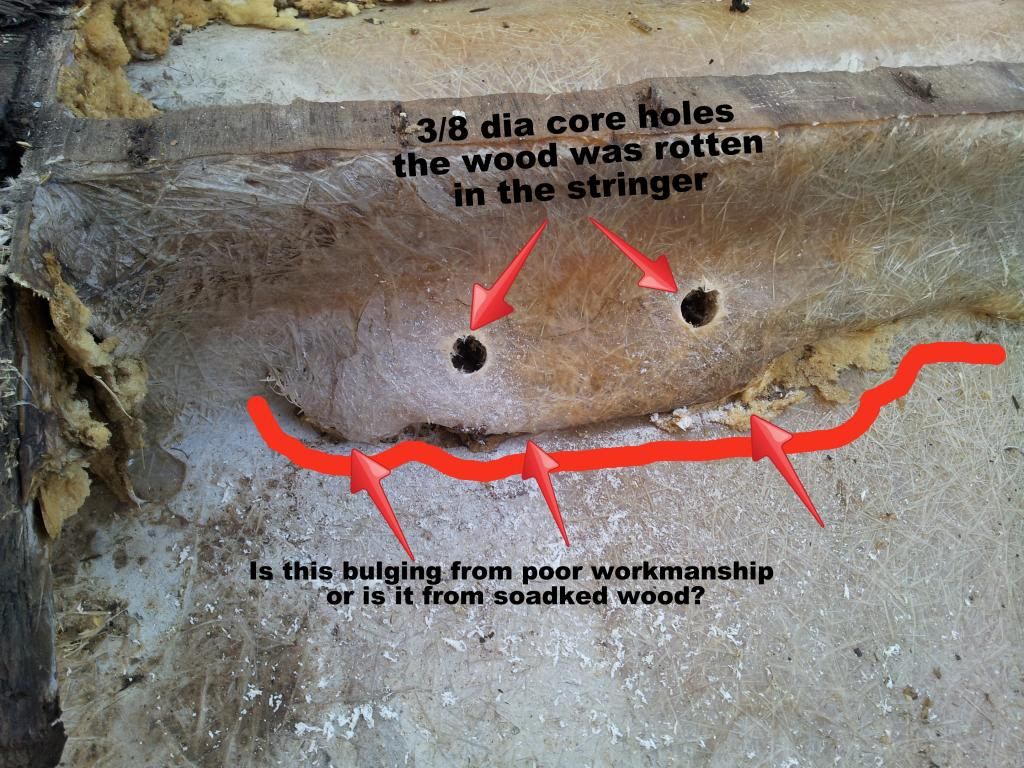

We took it out for a spin on Mothers day and had a blast and decided that we would get the interior done as the first step. After the upholstery guy started ripping into it I got a call and he said he pulled up the carpet and that I should come in and take a look. Well under the port side console the deck was really soft, actually pushed a screwdriver right through it without any force. I told him to go ahead and chop the floor and maybe we could repair it. Needless to say I was back in the shop the next day and he said the foam was saturated and he found some more spots. I had already read up on replacing a deck on iboats and decided to take it home and do it myself. After pulling out most of the foam I see now that the stringers are rotten in spots, not all the way down to the hull, but it will probably require me to tear out the old and replace with new wood and glass, then add some urethane pour in flotation foam for stiffness. The thing that I thought was a bit odd is that there are some cross braces over the stringers instead of full bulkheads, not sure if this is normal and if it is should I just rebuild it that way or would it be better to extend it to the hull? Also I noticed at the base and other areas of the stringers the fiberglass is bulging out. Looks like it might be bad workmanship from the factory (see in the pics), but I guess it could just as well be that the wood had adsorbed water and swelled the glass?

Is it safe to do a deck replacement without removing the cap and leaving it on the trailer? I'm tight on space and don't have the equipment to pull it off of the trailer and create a cradle for it. I was thinking to replace stringers one at a time and to brace it by putting some boards across the cap and bolting them in where the cleats would be. This could give it more rigidity during the rebuilding.

Now the original expanding foam had no way to drain to the stern of the boat which is what may have lead to the wood rott. They just poured it between the stringers and from bow to stern no drainage. How do other people address the lack of draining to the bilge area? My thought was to put in a 1 to 2 inch pvc pipe that's coated with some type of release agent and then pour the foam in little sections and pull the pipe from each chamber as it hardens. I welcome any suggestions and experiences others have had luck with or even failure (what not to do). Also after reading other posts about foaming, I think that the foam in this boat was structural so I don't think that the pink or blue rigid foam would be a good substitute. I'm new to all of this so I could be wrong and it maybe a perfectly acceptable substitute for pour in.

Here are some pics, they make me cringe when I look at them.

Thank you for any feedback or assistance.

Happy boating all!

I've been reading up on a lot of great resto threads and appreciate all of the information that has been shared. It's a bit overwhelming at first to come in and try to soak it all up, but I'm working on it.

Anyhow so I purchased my first boat and it seemed like a good enough deal, 85 Four Winns 170 Candia deck boat. My wife wanted a pontoon and I wanted a ski boat, so this was an in-between that seemed to fit the bill. The interior needed work and the paint was faded and heavily oxidized, but no cracks in the hull and the motor is strong so I purchased it well knowing that all had to be done and probably more, boy was I right.

We took it out for a spin on Mothers day and had a blast and decided that we would get the interior done as the first step. After the upholstery guy started ripping into it I got a call and he said he pulled up the carpet and that I should come in and take a look. Well under the port side console the deck was really soft, actually pushed a screwdriver right through it without any force. I told him to go ahead and chop the floor and maybe we could repair it. Needless to say I was back in the shop the next day and he said the foam was saturated and he found some more spots. I had already read up on replacing a deck on iboats and decided to take it home and do it myself. After pulling out most of the foam I see now that the stringers are rotten in spots, not all the way down to the hull, but it will probably require me to tear out the old and replace with new wood and glass, then add some urethane pour in flotation foam for stiffness. The thing that I thought was a bit odd is that there are some cross braces over the stringers instead of full bulkheads, not sure if this is normal and if it is should I just rebuild it that way or would it be better to extend it to the hull? Also I noticed at the base and other areas of the stringers the fiberglass is bulging out. Looks like it might be bad workmanship from the factory (see in the pics), but I guess it could just as well be that the wood had adsorbed water and swelled the glass?

Is it safe to do a deck replacement without removing the cap and leaving it on the trailer? I'm tight on space and don't have the equipment to pull it off of the trailer and create a cradle for it. I was thinking to replace stringers one at a time and to brace it by putting some boards across the cap and bolting them in where the cleats would be. This could give it more rigidity during the rebuilding.

Now the original expanding foam had no way to drain to the stern of the boat which is what may have lead to the wood rott. They just poured it between the stringers and from bow to stern no drainage. How do other people address the lack of draining to the bilge area? My thought was to put in a 1 to 2 inch pvc pipe that's coated with some type of release agent and then pour the foam in little sections and pull the pipe from each chamber as it hardens. I welcome any suggestions and experiences others have had luck with or even failure (what not to do). Also after reading other posts about foaming, I think that the foam in this boat was structural so I don't think that the pink or blue rigid foam would be a good substitute. I'm new to all of this so I could be wrong and it maybe a perfectly acceptable substitute for pour in.

Here are some pics, they make me cringe when I look at them.

Thank you for any feedback or assistance.

Happy boating all!