62cruiserinc

Petty Officer 1st Class

- Joined

- Oct 30, 2009

- Messages

- 295

I have a 1984 Larson 19'. The previous owner put 1/2" pressure-treated plywood over the original floor, probably because it was soft. This is my first boat, so if I don't use the correct terminology please forgive me.

I removed the PT plywood and the original floor was rotted in much of the rear 2/3 of the boat. There are two stringers about 2' apart that run from the transom up to the console. It looks like the floor rotted top down, as the stringers are good except for some spots where the top inch has rotted. The stringers are about 8" high and 1" thick.

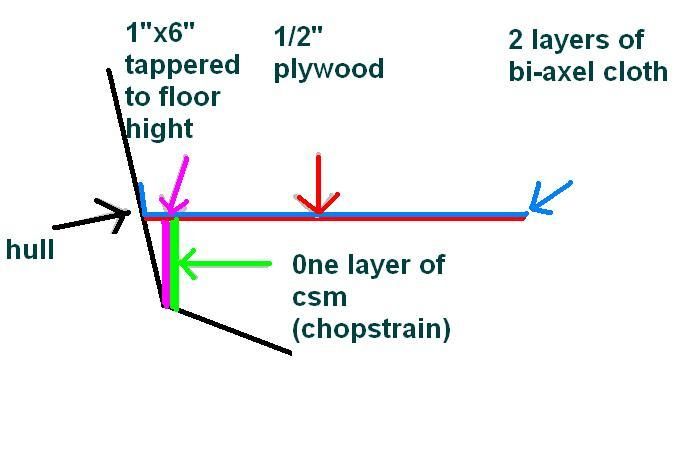

The plan for this year is to repair the floor and stringers so the boat can be used this year and then do a thorough restoration-type repair over the winter (I have a heated shop). I probably could have left it as it was for this year, but I wanted to improve it. I am planning to remove the rotted top inch of the stringers and attach a second stringer to the originals ("sister" them in housebuilding terminology). Then I will put new 1/2" PT plywood on the floor. I realize this is not a good permanent solution, but it will have to do for this summer.

The question I have is about the floor plywood. The original plywood is supported by the two parallel stringers that are about 2' apart (1' on each side of the centerline). These are the only stringers. There is foam between the floor and the fiberglass except between the two stringers (the bilge area). The plywood edge along the hull doesn't have any support under it, only the foam. The edge is also glassed to the hull along its length (for a width of about 6-8"). There are several areas along one side where the fiberglass is not attached to the hull, I don't know if it was originally attached and then cracked along the hull/floor line or not. My questioin is: Is the floor glassed to the hull to make the joint waterproof or does the floor act as a support for the hull to keep it from distorting? Same question for the floor-to-transom joint.

The reason I ask this question is that I need to know if I should glass the joint even for this temporary repair.

Thanks

Steve

I removed the PT plywood and the original floor was rotted in much of the rear 2/3 of the boat. There are two stringers about 2' apart that run from the transom up to the console. It looks like the floor rotted top down, as the stringers are good except for some spots where the top inch has rotted. The stringers are about 8" high and 1" thick.

The plan for this year is to repair the floor and stringers so the boat can be used this year and then do a thorough restoration-type repair over the winter (I have a heated shop). I probably could have left it as it was for this year, but I wanted to improve it. I am planning to remove the rotted top inch of the stringers and attach a second stringer to the originals ("sister" them in housebuilding terminology). Then I will put new 1/2" PT plywood on the floor. I realize this is not a good permanent solution, but it will have to do for this summer.

The question I have is about the floor plywood. The original plywood is supported by the two parallel stringers that are about 2' apart (1' on each side of the centerline). These are the only stringers. There is foam between the floor and the fiberglass except between the two stringers (the bilge area). The plywood edge along the hull doesn't have any support under it, only the foam. The edge is also glassed to the hull along its length (for a width of about 6-8"). There are several areas along one side where the fiberglass is not attached to the hull, I don't know if it was originally attached and then cracked along the hull/floor line or not. My questioin is: Is the floor glassed to the hull to make the joint waterproof or does the floor act as a support for the hull to keep it from distorting? Same question for the floor-to-transom joint.

The reason I ask this question is that I need to know if I should glass the joint even for this temporary repair.

Thanks

Steve