redstrat

Petty Officer 1st Class

- Joined

- Dec 29, 2011

- Messages

- 202

Ok, I just got my 1989 block back from being machined. They took it .020 over with diamond honing for a cost of $200. Seems mine was the first outboard motor to be done on their new $50k machine. I hope this is a good thing. I was going to send pictures but I can't seem to manage attachments anymore. Anyone else having this problem? I am making a list of parts and I have a few questions for those who have done this before.

1. I pressed out the wrist pins without the special spacer tool. Have I buggered up the bearings and/or the connecting rods?

2. All of the connecting rods appear to have been installed upside down ( V notch facing down with the intake baffle on the right. Have you guys encountered this and does it matter?

3. I plan on using Wisco pistons. Will the bearings I have service this application?

4. One connecting rod is slightly blue. Should I be looking to replace it?

5. Should I have ported before having it honed, or can I still proceed?

6. Frank, I know I read somewhere your recommendations about cutters and speeds for porting but I can't seem to find them now. If you could refresh my memory I would appreciate it greatly. I want to square the bypass side and slightly chamfer the exhaust.

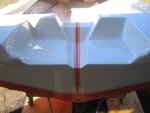

I guess that's it for now. Thanks to all for your anticipated help. I'll keep updating this thread as I go which may take some time (two kids in college). I am also putting energy into the resto/mod of my 16' Checkmate as the weather allows me to work outside. Hoping to hit the water next season. Thanks, Mark

1. I pressed out the wrist pins without the special spacer tool. Have I buggered up the bearings and/or the connecting rods?

2. All of the connecting rods appear to have been installed upside down ( V notch facing down with the intake baffle on the right. Have you guys encountered this and does it matter?

3. I plan on using Wisco pistons. Will the bearings I have service this application?

4. One connecting rod is slightly blue. Should I be looking to replace it?

5. Should I have ported before having it honed, or can I still proceed?

6. Frank, I know I read somewhere your recommendations about cutters and speeds for porting but I can't seem to find them now. If you could refresh my memory I would appreciate it greatly. I want to square the bypass side and slightly chamfer the exhaust.

I guess that's it for now. Thanks to all for your anticipated help. I'll keep updating this thread as I go which may take some time (two kids in college). I am also putting energy into the resto/mod of my 16' Checkmate as the weather allows me to work outside. Hoping to hit the water next season. Thanks, Mark