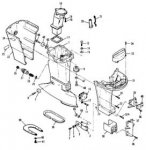

1989 Force 150 (1508F9A)

Started on the tear down this afternoon.

Carbs/Fuel Pumps off

Throttle Assembly off

Cylinder Head off

Ignition Modules off

Flywheel (Finally F%^&*n off) (make sure you have 2.5lb hammer, puller, heat, crowbar, lots of time, know lots of swear words to get this off)

Run into my first potential part needing replacement. On the stator (see statorbolt picture) one of the nuts has metal raised around it, I would assume this is not normal??? Probably should be replaced?

I'll try and keep taking pictures as I go along for anyone else needing to do a rebuild.

Started on the tear down this afternoon.

Carbs/Fuel Pumps off

Throttle Assembly off

Cylinder Head off

Ignition Modules off

Flywheel (Finally F%^&*n off) (make sure you have 2.5lb hammer, puller, heat, crowbar, lots of time, know lots of swear words to get this off)

Run into my first potential part needing replacement. On the stator (see statorbolt picture) one of the nuts has metal raised around it, I would assume this is not normal??? Probably should be replaced?

I'll try and keep taking pictures as I go along for anyone else needing to do a rebuild.