Re: Friscoboater's 1986 Glastron Carlson CVX-18 Complete restoration thread

This is not in disagreement w/ the above, it is solely for information:

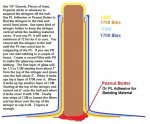

1708 has 0.75 oz CSM on the 'back'

the CSM most often used is 1.5 oz

CSM is also available in 2 oz as well, and I think I've seen 1 oz, but don't hold me to it

.............

CSM will have less print thru of the weave then 1708, so it should leave an easier surface to fill, smooth & fair prior to gelcoat or paint....

As Jay noted, there are many ways to accomplish similar goals. Having done a couple previous glass projects Jay knows how to make resin & cloth work for him & the way he works it & wets it out. Others may not have as much success skipping the CSM.

CSM contains soluble compounds that dissolve in resin, making it easier to get good contact, conform to contours, and sufficiently bond w/ the subsurface it's applied to. CSM often reduces the likelihood that a layup of will have a layer or 2 of cloth that gets starved of resin (doesn't have enough resin to correctly bond), and is often called the

resin rich layer in a layup schedule. For similar reasons, CSM is often used between each layer of 1708, to decrease the likelihood of insufficient bonding between layers.

If we could all do work of Jay's (and other's caliber @iboats) iboats would not be such a busy, popular spot

I too would not be neck deep in multiple resto's if not for the guys putting the info out @iboats and via videos.

Thanks Jay, my Admiral may not share my thankfulness :facepalm: