Re: Fuel Injection

It must be a marine certified system. Automotive systems can't be used in a marine engine, not only can't you use the O2 sensor, but the fuel mapping, timing and everything else for that matter, is way off.

If you know how to tune, and have the right equipment you can. I have done it. I was just getting ready to start a new post on this.

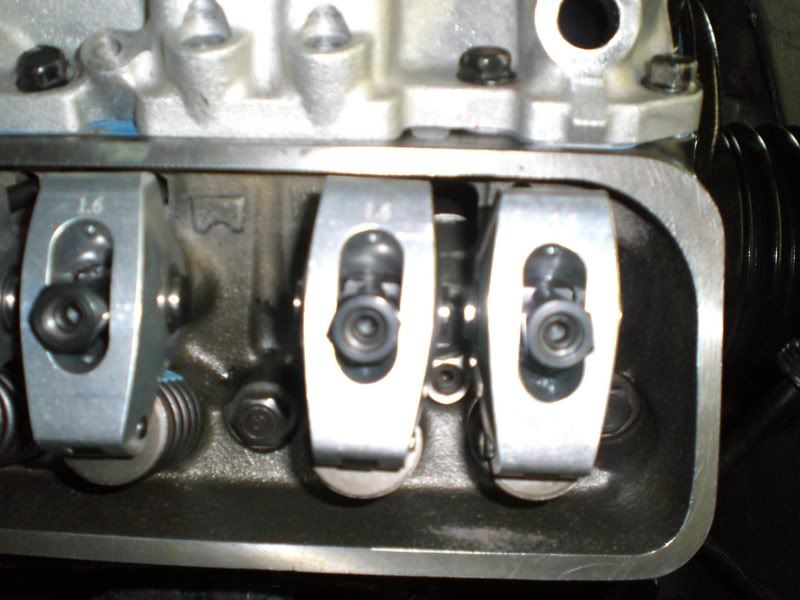

I converted my 305 to MPFI fuel injection. I used an Eldelbrock MPFI intake that I ran on my truck for a while. I built a 383 for my truck and the MPFI injectors would not feed the motor so I went to a BB TBI. I just never got rid of the MPFI intake. I bought my boat 2 years ago, this past fall I decided to get rid of the 2 barrel Rochester, since it needed a rebuild. When I pulled the intake off I noticed the little 305 was a roller block. One thing led to another and I ended up pulling the heads, ported them, valve job, machined for screw in studs, new valve springs, and cut the valve guides down for the extra lift from the LT4 roller cam that I was going to install. I converted the motor over to full roller (some more parts I had lying around). The LT4 cam has a smooth idle with little overlap so water reversion is not a problem. Since the intake is aluminum I coated the coolant passage with Por 15 to stop corrosion.

I am using an ECM out of a 94-95 Chevy truck or Astro van part number 16197427. This is the same ECM that is in my 94 full size Blazer. I am very familiar with this ECM ands its a good choice for this project since it can be used to run a TBI or a MPFI setup. The distributor is a GM small cap EFI distributor that was in many gm vehicles in the late 80's early 90's. For tuning this setup I have disabled the electronic transmission, EGR, 02 sensor, Vehicle speed sensor...etc. I am only using the basics to run the engine, MAP sensor, IAC, Temp sensor, and TPS. The ECM is also set to stay in open loop all the time which means it will not look for the 02 sensor. I did get a little crafty with Idea of using a O2 sensor. I made a plate that bolts to where the EGR valve used to be, tapped it out and put the 02 sensor on the exhaust side of the plate. I may try to run it in closed loop this summer when know everything else is right. I can also use the same port to check my AFR with my wide band 02 sensor, to make sure I am not going lean at WOT. You do have to be very careful with timing and fuel since a boat runs high RPM all the time you could very easily burn a piston up if you went lean. I have all my fuel tables a little on the rich side, with about 31* total timing advance.

The tuning software I use is free and is called Tuner Pro Rt. I also use it to data-log all the engine info threw the factory GM ALDL diagnostic port. I can view everything the engine is doing on my laptop.

There is also TunerCat but its not free nor as flexible as Tuner Pro

Oh, and the boat runs very well, it fires right up every time you turn the key. I have only run it in the driveway with my hose hooked to it. Its been to cold to take it out and the water pump is out of my lower unit.