kdiddle

Petty Officer 2nd Class

- Joined

- Mar 22, 2018

- Messages

- 147

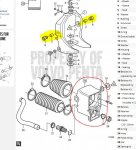

So while I have my drive unit (DP-SM) off, I was going to replace my gimbal bearing, but my Seloc manual goes into removing the entire pivot assembly (and marked as Difficult due to all the special tools required and such) before going into removing the gimbal bearing. This might be a completely stupid question, but can the gimbal not be knocked out with the pivot housing in place? I plan on also replacing the u-joint bellows, and it seems like you should be able to knock it out from inside the transom. Is that not the case?